"When investing in capital equipment, ROI and long-term reliability are my top priorities. The precision and consistency this line delivers for high-temperature media directly translates into significantly reduced material waste and higher throughput for our clients. This isn't just a machine; it's a strategic asset for scaling high-quality filter production."

JullyZhang - Operations Manager

Filtration manufacturers today face increasing demand for consistent, high-quality filters. Manual processes are slow, prone to errors, and often waste materials. That’s where automated fiberglass folding production lines come in—they revolutionize filter manufacturing with speed, precision, and reliability.

Seamless Integration of Cutting and Folding

These production lines combine multiple stages into a single, continuous workflow. The process begins with material feeding and cutting. Advanced pre-cutting systems adjust speed, width, and thickness to match product specifications. Lines are stabilized with pneumatic rollers and tension mechanisms, ensuring smooth transport to the folding machine.

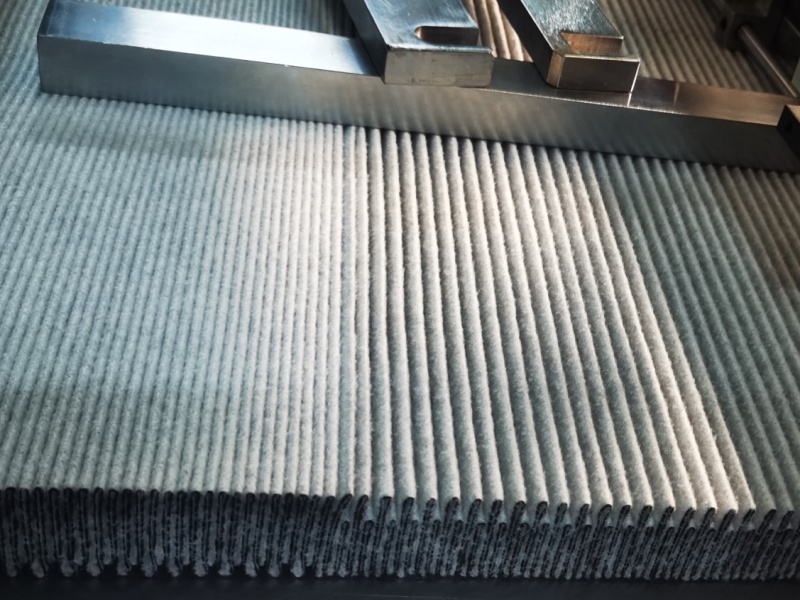

Precision Folding for High-Quality Filters

The folding machines use dual servo-controlled blades to fold filter paper accurately. Adjustable fold heights and line spacing allow for customization according to product needs. Aluminum and pressure plates specially designed for fiberglass prevent damage while maintaining consistency across every batch.

Smart Control for Maximum Output

Modern production lines include touch-screen interfaces, PLCs, servo motors, and precision reducers to synchronize operations from start to finish. This automation reduces human error, allows real-time adjustments, and ensures that production speeds remain optimal without sacrificing quality.

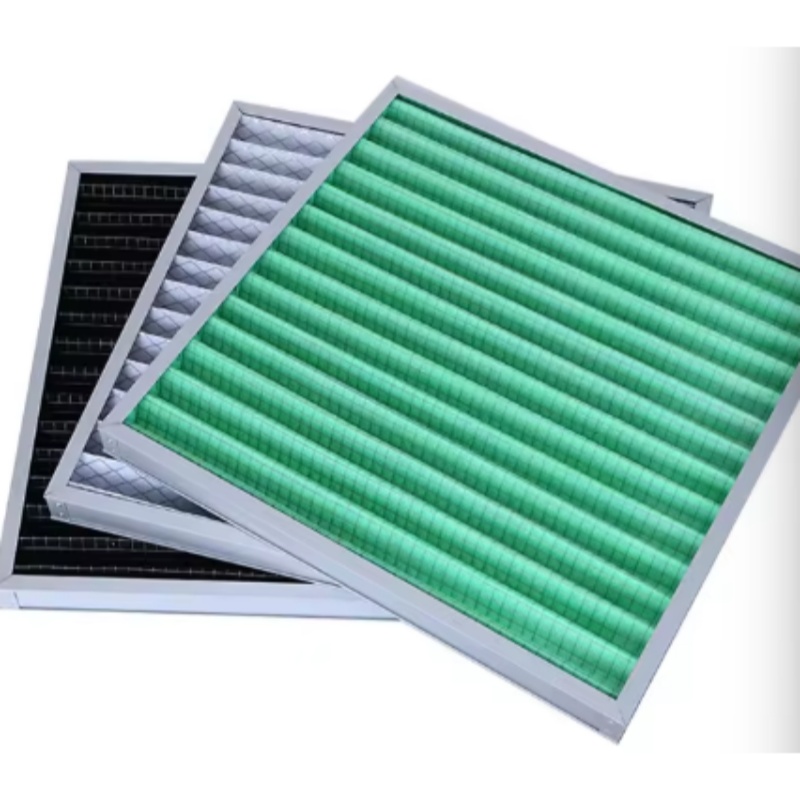

Applications Across Industries

These machines are versatile and support production for automotive air filters, HVAC systems, and industrial filtration products. They allow manufacturers to meet international standards and keep up with growing market demands while maintaining profitability.

The Benefits of Automation

Automated production reduces labor costs, minimizes material waste, and delivers consistent output. Companies can produce filters faster, more accurately, and at a lower overall cost, making these lines a vital investment for modern filtration factories.

Automation is no longer optional in filter manufacturing—it’s essential. High-temperature fiberglass folding production lines combine precision, efficiency, and durability, enabling manufacturers to stay competitive while producing top-quality filters.