Full-Auto Blade Pleating Production Line: The Core Driver of Filter Element Precision Manufacturing

Jan 31, 2026

In the era of increasing demand for air quality and industrial purification, the quality of filter elements directly determines the performance of air purifiers and industrial air filters. The Fully Automatic Blade Pleating Production Line has become the backbone of filter manufacturing. As specialized equipment such as Air purifier paper folding production line and air filter folding equipment, it solves the pain points of traditional manual folding, such as inconsistent pleat size and low efficiency, providing a reliable guarantee for mass production of high-precision filter elements. For manufacturers pursuing quality and scale, this production line is an indispensable technical investment.

Technical Parameters: Balancing Precision and Efficiency

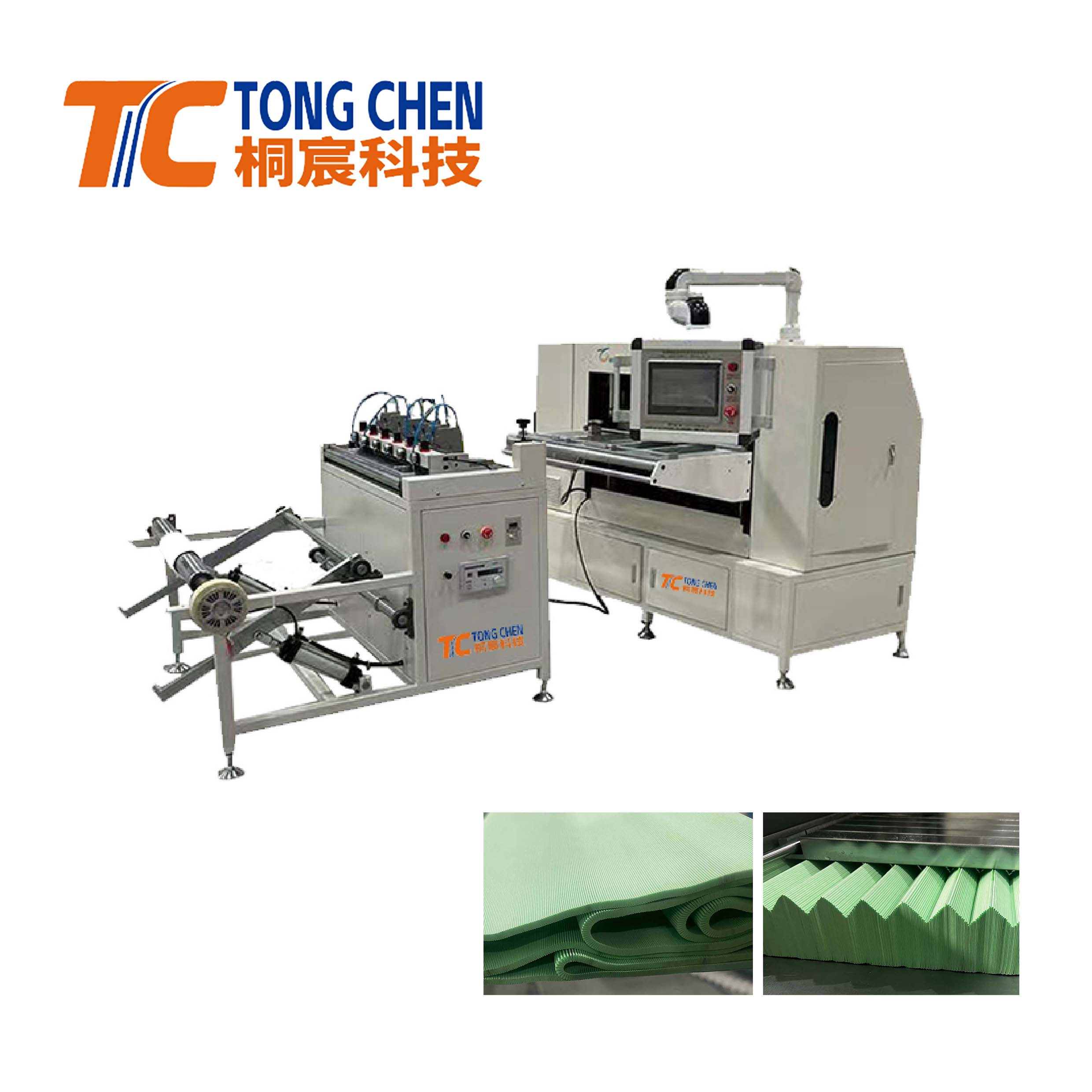

The Knife Paper Folding & pleating machine integrates three key modules to achieve end-to-end automation: automatic paper unwinding rack, pre-slitting paper feeder, and filter paper folding machine. Each component is designed to complement each other, ensuring stable operation. The pre-slitting paper feeder, with an adjustable paper feeding speed of 0.5m/min~25m/min and filter paper width of 25~850mm, can be customized according to different filter element specifications. Equipped with a 0.55kw motor and 380V/50Hz power supply, it uses frequency converter stepless speed regulation and pneumatic knives, plus an infrared monitoring system to synchronize with the folding machine’s speed, ensuring precise and error-free slitting. The filter paper folding machine, as the core module, weighs 450kg with dimensions of 1800×1500×1650mm, perfectly matching the pre-slitting feeder’s 1280×1100×1200mm size for factory layout optimization.

The technical parameters of the Fully Automatic Blade Pleating Production Line are tailored to the needs of filter manufacturing. The folding machine offers an adjustable pleat height range of 5-70mm (adaptive to different materials) and a folding speed of 0-280 folds per minute, which can be flexibly adjusted according to production requirements. Its power configuration is efficient and stable: 1.8kw main motor, 0.4kw lifting motor, and 6kw preheating power, with a temperature control range of 0-260℃, enabling rapid shaping of filter paper pleats. Both the pre-slitting feeder and folding machine operate at 0.6Mpa working pressure, ensuring consistent performance of pneumatic components. These parameters not only meet the precision requirements of small household air purifier filters but also adapt to the high-volume production needs of industrial air filter elements.

Core Features: Enhancing Operability and Product Quality

The Blade pleating machine stands out with user-friendly and high-performance features. The pre-slitting feeder’s automatic feeding function and adjustable rollers at both ends of the conveying system simplify operation, reducing labor intensity. The folding machine’s paper feeding platform is equipped with a limiting device to prevent material deviation, ensuring stable input of filter paper of various sizes. Controlled by upper and lower servo motors, the folding mechanism achieves fast and precise pleating, while the dual heating plates (each with three heating discs) allow temperature adjustment via a display screen, enhancing pleat firmness. Additionally, the dot-counting device enables real-time production monitoring, and the chrome-plated rear workbench with tempered glass ensures durability and operational safety. These features collectively reduce human errors and material waste, improving production yield.And it can also be folded into a "W" shape according to the customer's requirements.

Application Scenarios & Future Trends: From Household to Industrial Integration

As a dedicated Air purifier paper folding production line and air filter folding equipment, this production line has strong scenario adaptability. It can process non-woven fabrics, glass fiber, and other common filter materials, producing filter elements for household air purifiers, commercial air purifiers, and industrial dust collectors. Looking ahead, the Integrated Blade Pleating Automatic Production Line represents the development direction—integrating slitting, folding, shaping, and counting into one system to further shorten production cycles. With the advancement of intelligent manufacturing, this production line can be connected to digital management systems, enabling remote monitoring and parameter adjustment, helping manufacturers achieve lean production. In the context of stricter environmental regulations and rising consumer demand for air quality, this integrated and intelligent production line will become a key competitive advantage for filter enterprises.

Read More