"When investing in capital equipment, ROI and long-term reliability are my top priorities. The precision and consistency this line delivers for high-temperature media directly translates into significantly reduced material waste and higher throughput for our clients. This isn't just a machine; it's a strategic asset for scaling high-quality filter production."

JullyZhang - Operations Manager

As high-temperature filtration applications continue to expand across industries such as industrial dust collection, cleanroom engineering, energy, and advanced manufacturing, customers are demanding greater consistency, higher thermal resistance, and long-term production stability from fiberglass filter media.In response to these market needs, we have successfully developed and exported China’s first export-grade high-temperature fiberglass folding paper production line. Designed to meet—and in several key aspects exceed—European (German) technical standards, this production line now represents a new global benchmark in high-temperature fiberglass filter media manufacturing.

1.Engineered Specifically for High-Temperature Fiberglass Materials

This production line is purpose-built for the continuous and stable processing of non-separator high-temperature fiberglass filter media. The system integrates all critical processes into a single, coordinated line, including:

• Fiberglass strip unwinding system

• Material feeding rack

• Pre-slitting and paper feeding unit

• Strip conveying system

• Upper and lower strip automatic synchronization mechanism

• Filter media automatic synchronization system

• Strip tension control system

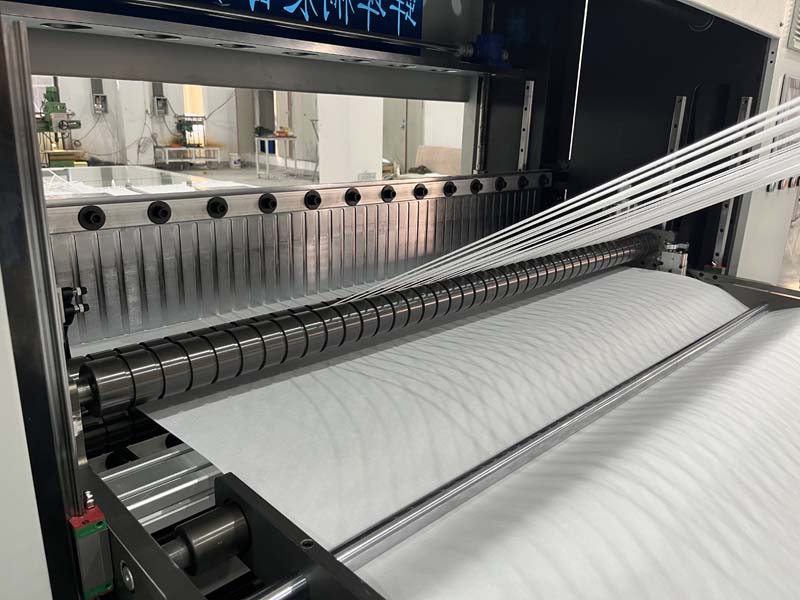

• High-precision folding and forming unit

The integrated design ensures smooth material flow, minimizes manual intervention, and delivers consistent product quality throughout long production cycles.

2.High-Precision Servo Synchronization for Stable Folding Quality

High-temperature fiberglass materials are inherently rigid and fragile, making precise control essential during folding. To address these challenges, the production line adopts full servo control and electronic cam technology across critical processes.

Key performance features include:

• Full servo-driven synchronization between fiberglass strips and filter media

• Electronically controlled folding knives for precise fold height and spacing

• Adjustable tension control using powder brakes, air shafts, and tension regulators

• Automatic upper and lower strip slitting synchronized with the folding process

With a folding speed of up to 60 pleats per minute and an adjustable pleat height range of 25-300 mm, the system delivers both high efficiency and exceptional folding accuracy.

3.Structural Design Focused on Material Protection and Long-Term Stability

Every mechanical detail of the production line has been optimized to protect fiberglass materials and ensure long-term operational reliability:

• Precision-machined aluminum pressing plates designed specifically for fiberglass folding, preventing material damage

• Reinforced aluminum frame structure for high rigidity and vibration-free operation

• Chrome-plated shafts for enhanced wear resistance and extended service life

• Guided feeding platforms with strip-positioning devices to maintain stable material input

These design choices enable the system to operate reliably under continuous, high-load production conditions

4.Export-Grade Electrical Configuration for Global Markets

The production line is equipped with a robust, internationally proven electrical control system:

• Full digital servo motors and drives

• INOVANCE PLC five-axis control unit with 10-inch touchscreen HMI

• High-precision gear reducers

• Industrial-grade pneumatic and instrumentation components

The control interface is intuitive and easy to operate, allowing overseas customers to achieve fast commissioning and simplified maintenance.

5.More Than a Machine — A Reliable Production Solution

As China’s first successfully exported high-temperature fiberglass folding paper production line, this system has already earned recognition from international customers for its stability, efficiency, and consistent product quality.We believe that advanced equipment is defined not only by technical specifications, but by its ability to operate reliably over time and continuously create value for customers.

If you are seeking a stable, export-grade, and future-ready solution for high-temperature fiberglass filter media production, our production line is designed to support your long-term success in global markets.