This machine is an essential piece of equipment in filter manufacturing lines, particularly suitable for air filters, oil filters, fuel filters, and industrial filtration materials. It is built with a robust frame, stable pneumatic system, and precise cutting control, ensuring smooth operation and reduced production waste.

High Cutting Accuracy:

Achieves smooth, precise, and burr-free cuts with minimal deviation, ensuring uniform material dimensions for consistent filter quality.

Adjustable Cutting Size:

Both cutting length and width can be customized to accommodate various filter types and material sizes.

Pneumatic-Driven System:

Operates with a stable 0.6 Mpa air pressure, offering reliable cutting force, low vibration, and extended component life.

Compact & User-Friendly Design:

Small footprint with simple operation, suitable for both standalone use and integration into automated production lines.

Durable Structure:

Manufactured with high-quality steel components, designed for long-term industrial use under continuous operation.

|

Parameter

|

Specification

|

|

Maximum trimming length

|

≤ 800 mm

|

|

Maximum cutting width

|

≤ 800 mm

|

|

Working air pressure

|

0.6 MPa

|

|

Power supply voltage

|

220V / 50Hz

|

|

Machine weight

|

220 kg

|

|

Dimensions (L × W × H)

|

1200 × 1300 × 1400 mm

|

The TCHQ-850 cross-cutting machine operates through a precision pneumatic cutting system.

During production, the filter material is fed onto the cutting platform, and when the preset length is reached, the pneumatic blade automatically performs a cross-cut with high accuracy.

This ensures:

Clean cutting edges with no material tearing or deformation.

Accurate trimming for each cycle.

Stable operation even under long-duration, high-speed conditions.

The machine can be easily connected to pleating machines, marking systems, or automatic counters, forming a complete automated filter production line.

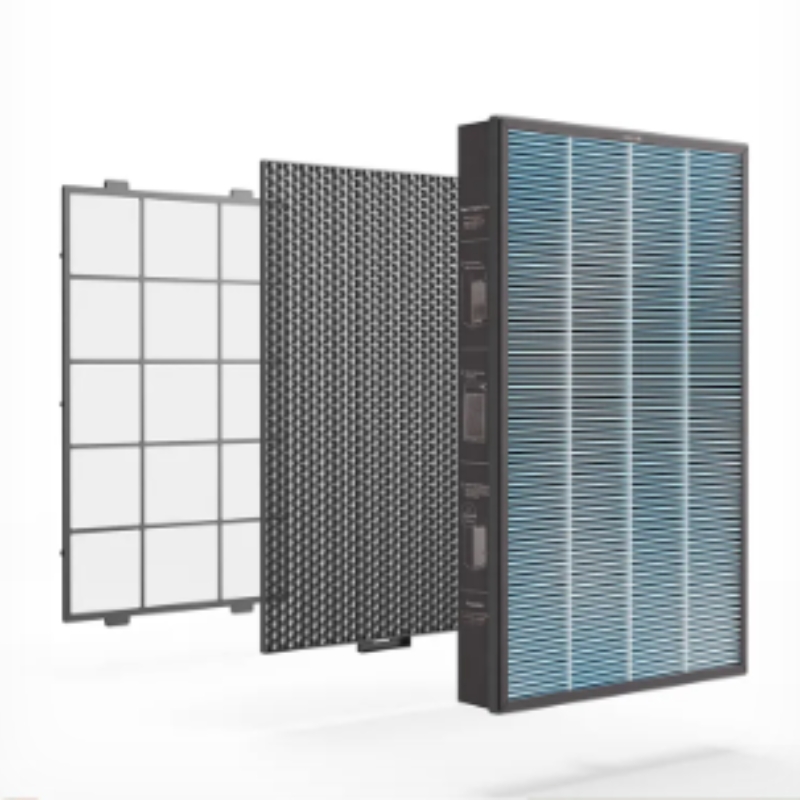

The TCHQ-850 is widely used across multiple industries requiring precision filter materials, including:

- Automotive Industry: Air, oil, and cabin filter media cutting.

- Industrial Filtration: Dust and hydraulic filter paper preparation.

- HVAC Systems: Filter paper trimming for air purification filters.

- Scientific Research & Laboratory Applications: Material sample preparation and small-batch testing.

- High operational precision and repeatability.

- Low energy consumption with minimal maintenance requirements.

- Easy setup and integration with existing equipment.

- Capable of handling filter paper, nonwoven fabric, fiber sheets, and composite materials.

- Strong adaptability to different production speeds and material types.

Each TCHQ-850 machine is rigorously inspected and tested before shipment.

Bengbu Tongchen Automation ensures:

- Stable cutting performance under long-term operation.

- Precision calibration of every cutting unit.

- Comprehensive technical support and after-sales service to guarantee optimal performance.

- Professional Manufacturer: Over a decade of experience in filter machinery R&D and production.

- Global Service Network: Reliable supply and technical support to clients worldwide.

- Customization Capability: Tailored solutions to meet specific filter production requirements.

- Consistent Innovation: Continuous upgrades to improve automation, accuracy, and user experience.

By choosing Bengbu Tongchen Automation, you’re choosing efficiency,

Product categories

Product categories