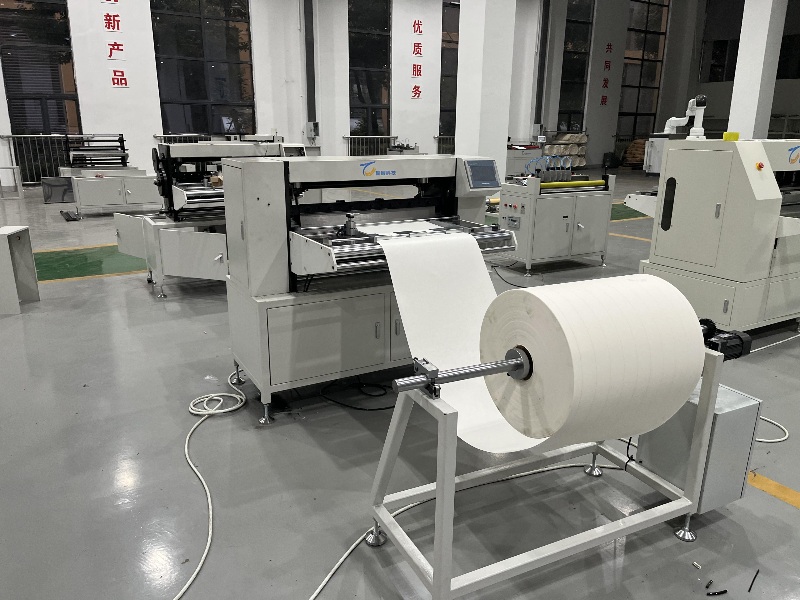

This model is ideal for the production of automotive filters, hydraulic filters, and industrial filter elements, ensuring consistent product accuracy and neat folding performance.

|

Item

|

Specification

|

|

Maximum Product Width

|

800 mm

|

|

Adjustable Folding Height

|

20 – 100 mm

|

|

Folding Speed

|

0 – 80 folds/min (non-polar adjustable)

|

|

Power Supply Voltage

|

380V / 50Hz

|

|

Motor Power

|

1.5 kW

|

|

Preheating Power

|

6 kW

|

|

Temperature Control Range

|

Ambient 0– 300°C

|

|

Working Air Pressure

|

0.6 Mpa

|

|

Machine Weight

|

450 kg

|

|

Dimensions (L × W × H)

|

1650 × 1750 × 1600 mm

|

The folding machine operates through alternate upper and lower knife mechanisms, which precisely fold filter materials with adjustable knife spacing. The system ensures uniform folding height, accurate dimensions, and smooth flatness across the material surface.

During operation, the filter paper undergoes:

- Automatic dot-marking and counting

- Folding processing

- Pre-heating and shaping

This integrated process provides excellent pleating precision and enhanced production efficiency.

Key Features & Advantages

- Alternate Knife Folding System: Ensures high folding precision and stable performance.

- Manual Adjustment Capability: Easily adjust knife spacing for different folding heights.

- Wide Material Compatibility: Suitable for filter paper, non-woven fabrics, and wire mesh.

- Pre-heating & Shaping Function: Guarantees smooth surface and consistent pleat form.

- Stepless Speed Control: Flexible folding speed to match various production requirements.

- Durable Construction: Heavy-duty design ensures reliable operation and long service life.

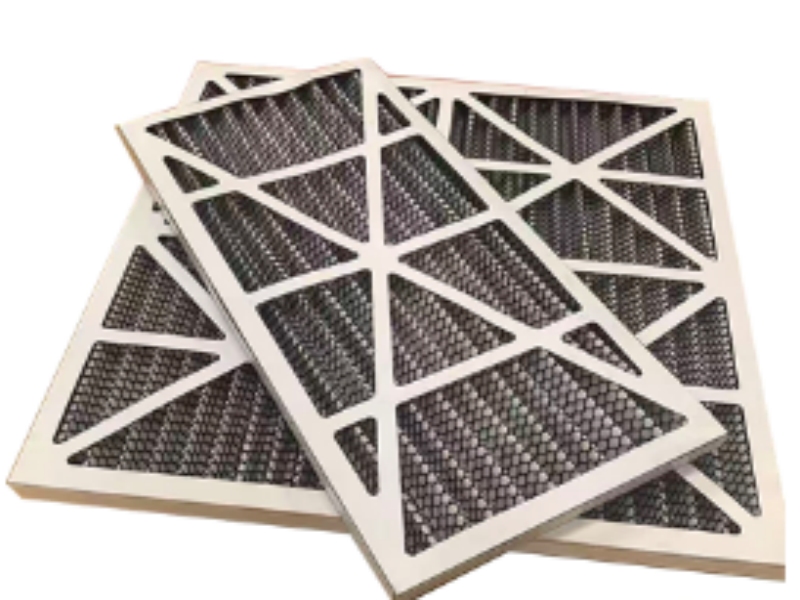

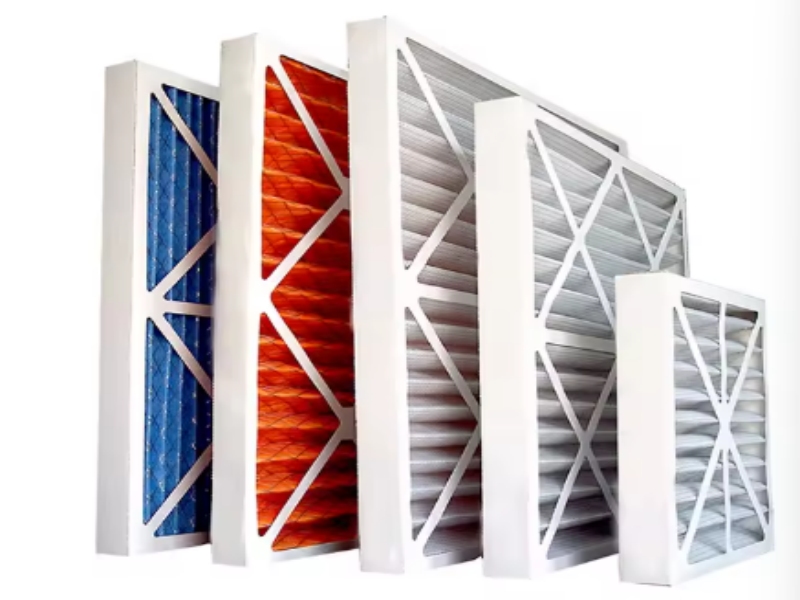

- Automotive Air and Oil Filters

- Hydraulic Filters

- Industrial Dust Filters

- Non-woven and Mesh Filter Production

- Multi-layer folding system

- PLC touch screen control system

- Integration with automatic feeding or gluing lines

- Custom folding height and heating settings

Product categories

Product categories