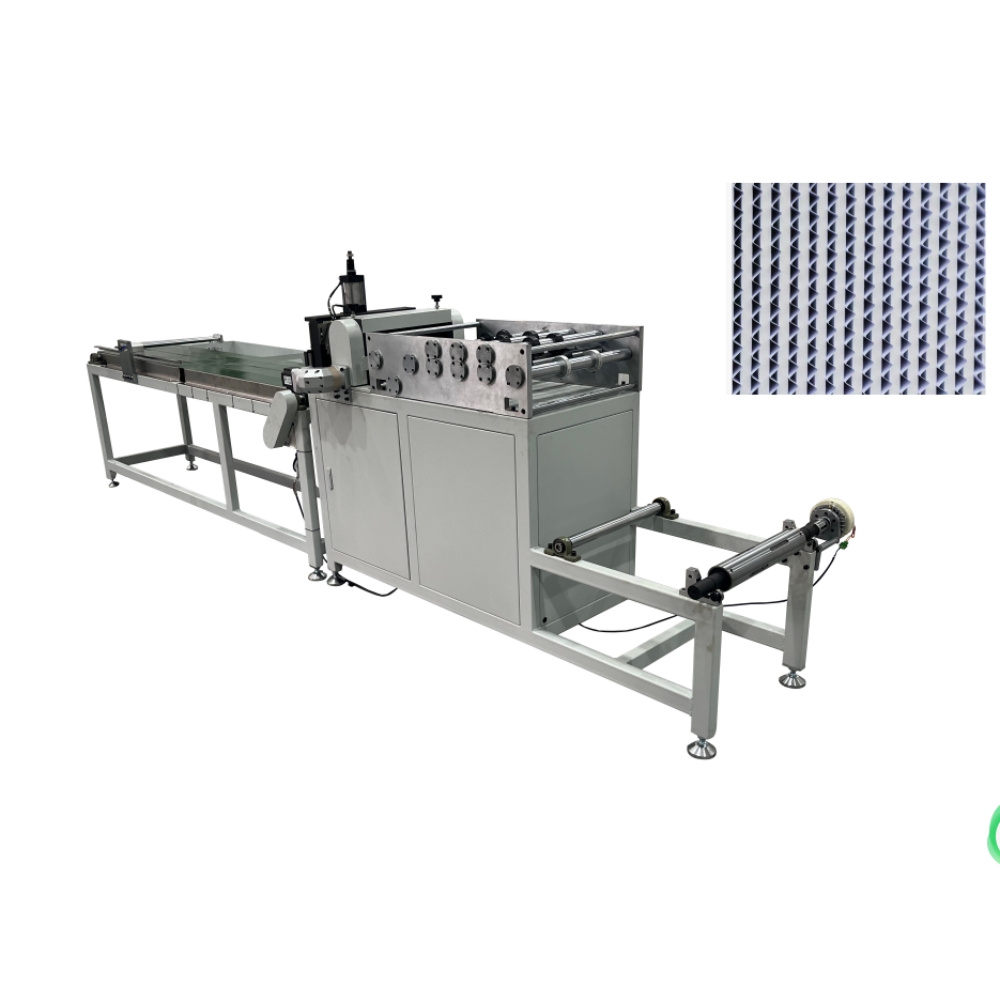

The 350mm Corrugating Machine is a state-of-the-art solution for producing aluminum foil and paper separators. Featuring a painted frame for precision and aesthetic appeal, the ergonomic layout allows easy roll replacement, adjustment, and operation. The process—from roll feeding and tension control to flanging, corrugation, sizing, cutting, and automatic discharge—is fully optimized for efficiency, quality, and minimal operator fatigue.

Process Workflow:

Rolled aluminum foil (paper) → Coiling → Tension unwinding → Tension feeding → Flanging → Corrugation pressing (heat setting) → Automatic sizing cutting → Automatic discharge

-

Unwinding Section: Magnetic powder brake with a dedicated motor ensures constant tension control, keeping aluminum foil straight for smooth flanging, corrugation, and cutting. Includes air-expandable shaft.

-

Inlet Tension Section: Adjustable tension rollers avoid uneven tension, ensuring stable production.

-

Flanging Section: Roller-type flanging continuously flattens and smooths aluminum foil edges to meet width requirements.

-

Corrugation Pressing Section: Replaceable corrugation rollers can be customized for height requirements; full roller group replacement requires no adjustment.

-

Sizing & Cutting Section: Pneumatic knives with induction sizing provide high precision cutting of corrugated sheets.

-

Automatic Discharge Platform: Pneumatic system automatically ejects finished corrugated sheets, simplifying collection and stacking.

-

High production efficiency (up to 30 sheets/min).

-

Fully customizable corrugation height (3–6mm) and sheet length.

-

Stable production due to tension-controlled feeding.

-

Ergonomic design improves operator comfort and safety.

-

Easy maintenance with accessible and replaceable components.

-

Suitable for both aluminum foil and paper materials.

-

Painted frame ensures durability and precision alignment.

| Parameter |

Specification |

| Material |

Aluminum foil (semi-hard, flat) or paper |

| Maximum Roll Diameter |

700 mm |

| Maximum Material Width |

320 mm |

| Material Thickness |

0.04 ± 0.005 mm |

| Corrugated Edge Width After Pressing |

3 mm – 10 mm |

| Corrugation Height |

3 mm – 6 mm (customizable) |

| Sizing Length |

Freely adjustable |

| Production Speed (Max) |

0 – 30 sheets/min |

| Power Supply |

380V, 50Hz |

| Compressed Air Requirement |

0.6 m³/min |

| Machine Dimensions (L × W × H) |

3800 × 950 × 1395 mm |

| Motor Configuration |

Three-phase motor |

| Mechanical Parts Treatment |

Shafts: electroplated hard chrome; Others: decorative nitro-iron and black treatment |

| Pneumatic Components Brand |

Jiahe brand, Harbin bearings |

| Instrument Installation |

Reasonable layout, easy to remove |

Equipment Composition & Configuration List

-

Motor: Three-phase motor

-

Mechanical Parts: Shafts treated with hard chrome; other parts treated with decorative black finish

-

Pneumatic Components: Cylinders, solenoid valves, and pressure regulators from Jiahe brand; bearings from Harbin

-

Standard Instruments: Installed for convenience and easy disassembly

-

Production of aluminum foil corrugated separators

-

Manufacturing of paper-based separators

-

Industrial packaging materials

-

Electronics and battery separator sheets

-

Custom corrugated sheets for industrial applications

-

Experienced in precision corrugating machinery manufacturing

-

Fully customizable solutions for corrugation height, sheet size, and material type

-

Ergonomic and safety-oriented machine design

-

High stability and efficiency for large-scale production

-

Strong after-sales service and spare parts support

Product categories

Product categories