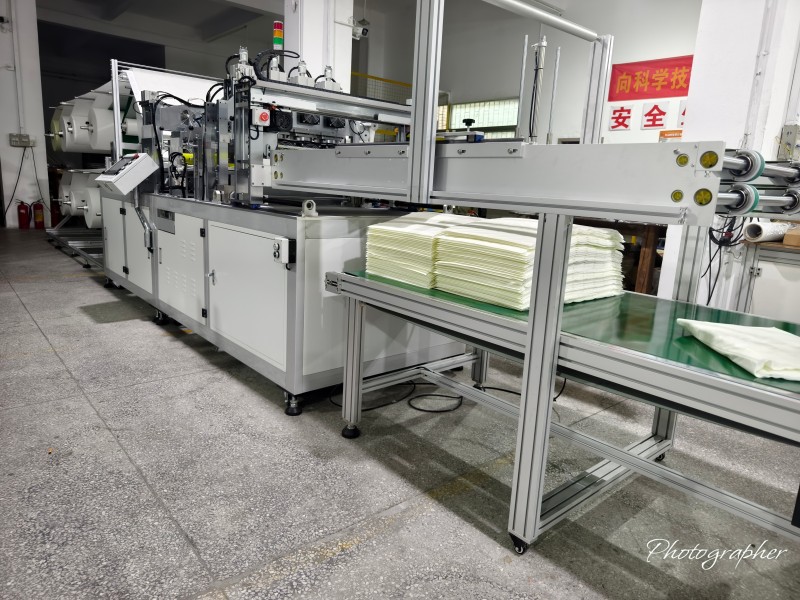

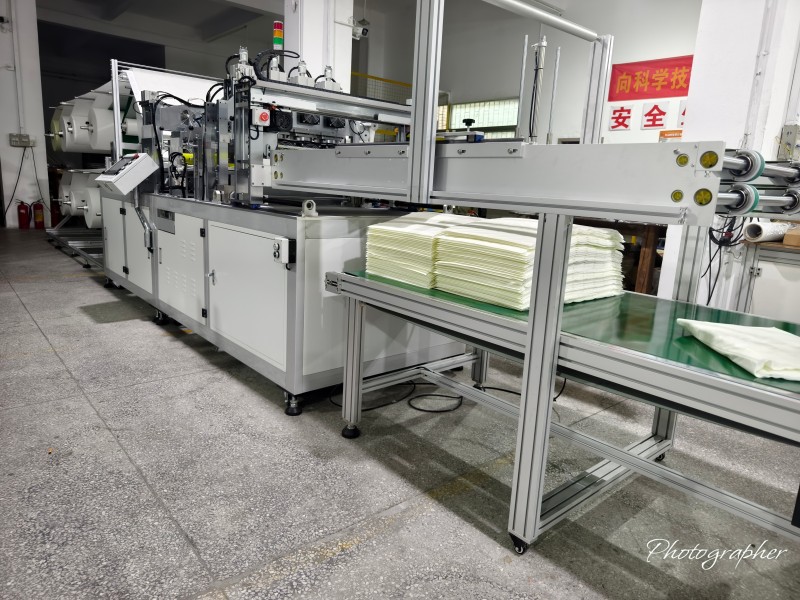

TheTC-7020 offers a multi-functional dual-mode system: slitting mode and rewinding mode, with options for single-output or dual-output production. It supports both rectangular right-angle filter bags and trapezoidal filter bags with adjustable angles—switchable via one button, with zero material loss.

The standard model produces filter bags up to 750mm width and 1800mm depth, meeting most mainstream requirements without mold replacement. For larger dimensions, customization is available. With precise ultrasonic welding, the finished bags feature clean, neat, and visually appealing cuts.

Slitting mode reaches 25–30 pcs/min, while rewinding mode reaches 20–25 m/min, depending on materials and bag size. Its automation, stability, and production capacity make it indispensable in the air purification industry.

-

Fully automated production line requiring only one operator

-

Supports slitting mode and rewinding mode

-

Single-output and dual-output options (dual-output doubles efficiency)

-

Capable of making right-angle rectangular and trapezoidal filter bags

-

One-click mode switching with zero material waste

-

High-speed ultrasonic composite welding for stable performance

-

Touchscreen operation with 100 memory recipes

-

Fault diagnosis, alarms, reminders, and intuitive controls

-

High efficiency:

-

Slitting: 25–30 pcs/min

-

Rewinding: 20–25 m/min

-

Produces high-quality bags with neat cuts and strong welds

-

Designed for mass production and reduced staffing

-

One of the highest performing machines in its category

-

Exceptional Efficiency: Dual-output mode doubles production and reduces ultrasonic weld frequency, extending ultrasonic machine life.

-

Flexible Production: Supports roll products and sheet products in one machine.

-

Precise Control: Multiple servo systems ensure accuracy in slitting, welding, edge trimming, and cutting.

-

Durable Construction: Reinforced aluminum frame with thick structural panels.

-

Customizable: Supports oversized bag customization beyond standard dimensions.

-

Superior Automation: Integrated PLC + HMI control system enhances productivity and reduces error rates.

-

Advanced Ultrasonic System: 14 high-power ultrasonic units ensure strong bonding and long operational stability.

-

Modern Air Purification Manufacturing Essential: Ideal for large-scale, integrated filter bag production.

| Category |

Details |

| Operating Modes |

Slitting Mode, Winding Mode |

| Max Bag Size |

Width: 750mm; Length: 3600mm (single output) / 1800mm (dual output) |

| Production Capacity |

Rewinding ≤22 m/min; Sheet ≤30 pcs/min (depending on size & material) |

| Welding Technology |

Ultrasonic Welding |

| Ultrasonic Power |

20kHz 1500W × 10 sets; 20kHz 2600W × 4 sets |

| Voltage |

380V, 3-phase |

| Power Consumption |

11–12.5 kW |

| Air Pressure |

0.5–0.8 MPa |

| Servo Motors |

4 sets (including 2 absolute-value servo motors) |

| Unwinding Racks |

9 reinforced aluminum material racks |

| Rewinding System |

1 rewinder, 3-inch pneumatic shaft, max Ø1000mm |

| Control System |

Mitsubishi FX5U PLC + Xinjie 10-inch HMI |

| Traction Rollers |

3 sets (steel shaft + rubber coating) |

| Cutting Method |

Gantry-type flying knife |

| Main Frame |

Reinforced aluminum + 12mm panels |

| Conveyor Length |

2m with electric width adjustment |

| Major Components |

Delta servo, Delta inverters, HONTKO encoder, AirTac cylinders/rails/solenoids, Siemens buttons |

-

HVAC medium-efficiency pocket filter manufacturing

-

Cleanroom filter production

-

Air purifier filter bag fabrication

-

Industrial dust collection systems

-

Melt-blown and non-woven filtration processing

-

Factory-scale filtration material conversion

-

OEM/ODM filter bag production

-

Large-scale air purification equipment manufacturers

-

Over 20 years of expertise in automated non-woven deep-processing equipment

-

Continuous innovation with upgraded technical solutions

-

Strong global customer base in air filtration and environmental equipment

-

Professional customization for special bag sizes or production demands

-

High reliability, low failure rate, and industry-leading efficiency

-

Factory visit welcome — see real machines in operation

-

Quality-driven manufacturing that reflects TongChen’s long-standing reputation

Product categories

Product categories