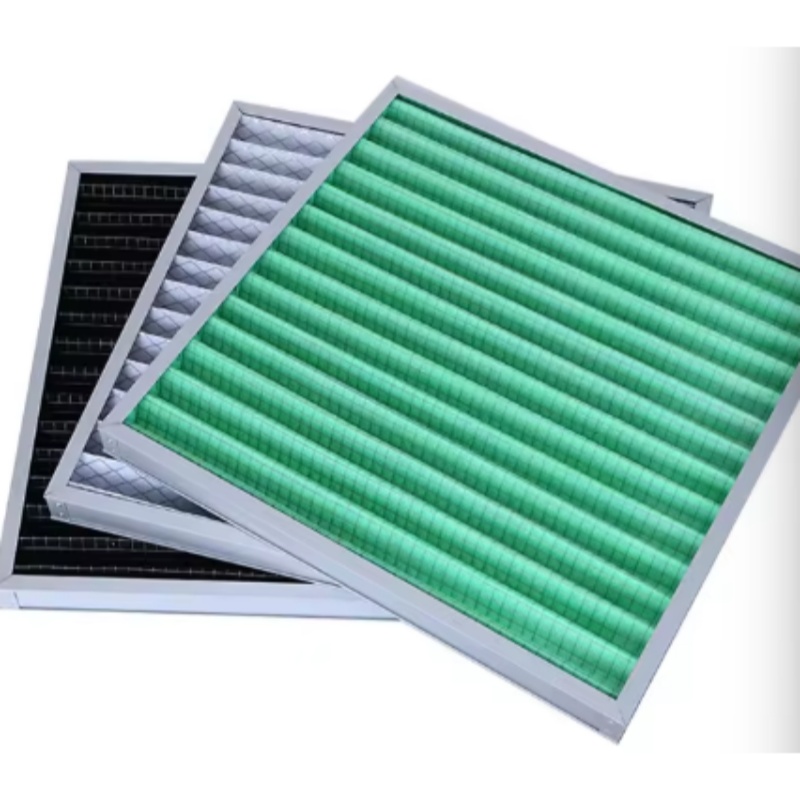

This production line is ideal for automotive, air purification, water filtration, and industrial filtration industries. It is engineered for high-speed production, consistent glue application, and flexible parameter adjustment to accommodate various filter specifications.

1. Integrated Automation – Combines feeding, pleating, and gluing for continuous and efficient production.

2. Computer Touchscreen Control – Intelligent interface for setting and monitoring speed, temperature, and glue parameters.

3. Precise Glue Control System – 50kg hot-melt glue unit with dual 26-point spray heads for even, accurate glue application.

4. Adjustable Folding Mechanism – Flexible pleating height and width to adapt to different filter materials.

5. High-Quality Components – Equipped with Hui Chuan motors, PLCs, and sensors for reliable and precise performance.

6. Energy Efficient and Durable – Built with robust materials and advanced control systems to ensure long lifespan and low maintenance.

| Pre-slitting Paper Conveyor |

|

Filter Paper Folder |

|

Gluing Machine (Model 55-700) |

| Parameter |

Specification |

|

Parameter |

Specification |

|

Parameter |

Specification |

| Adjustable paper conveyor speed |

0.5 – 12 m/min |

|

Maximum product width |

800 mm |

|

Maximum product width |

700 mm |

| Adjustable filter paper width |

32 – 800 mm |

|

Adjustable folding height range |

6 – 55 mm |

|

Adjustable folding height range |

6 – 55 mm |

| Power supply voltage |

220V / 50Hz |

|

Folding speed |

0 – 100 folds per minute |

|

Production speed |

4 – 25 m/min |

| Motor power |

0.55 kW |

|

Power supply voltage |

380V / 50Hz |

|

Glue strip spacing |

25.4 mm |

| Machine weight |

350 kg |

|

Motor power |

1.1 kW |

|

Number of glue strips |

2 × 26, each controlled by electronic valve |

| Dimensions (L × W × H) |

1500 × 1300 × 1100 mm |

|

Preheating power |

4 kW |

|

Glue-off control |

Automatic intermittent glue-off function |

| |

|

|

Temperature control range |

Ambient to 200°C |

|

Power supply voltage |

380V / 50Hz |

| |

|

|

Operating air pressure |

0.6 MPa |

|

Total power |

13 kW |

| |

|

|

Machine weight |

650 kg |

|

Operating air pressure |

0.6 MPa |

| |

|

|

Dimensions (L × W × H) |

1670 × 1720 × 1240 mm |

|

Machine weight |

500 kg |

| |

|

|

|

|

|

Glue machine dimensions (L × W × H) |

160 × 100 × 130 mm |

| |

|

|

|

|

|

Main machine dimensions (L × W × H) |

4000 × 130 × 160 mm |

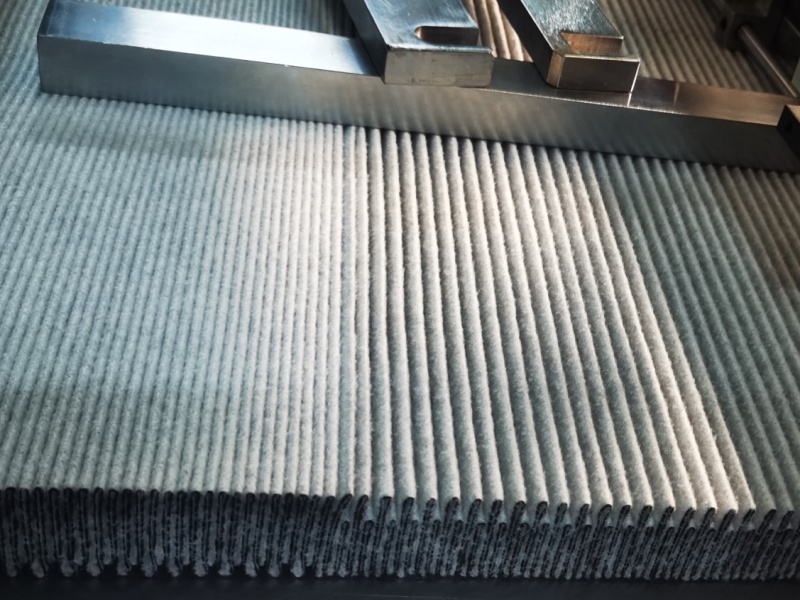

The production line starts by feeding and pre-slitting the PP filter material, followed by pleating (folding) to form a uniform wave structure. The gluing system, composed of dual 26-point spray heads, applies hot-melt adhesive strips with high accuracy. All major functions—speed, glue volume, and temperature—are controlled via a touchscreen PLC interface, ensuring synchronized operation of each component.

The pleating mechanism can move vertically and horizontally, enabling adjustment for various filter sizes and thicknesses. This flexible design allows seamless switching between different product specifications with minimal downtime.

|

Component

|

Specification / Brand

|

|

Motor

|

Hui Chuan

|

|

Touchscreen

|

7-inch, Hui Chuan

|

|

PLC Programmable Controller

|

Hui Chuan (Taiwan)

|

|

Electrical Components

|

Custom-made high-precision sensors and imported relays

|

|

Mechanical Parts

|

Shafts plated with hard and decorative chromium; others blackened

|

|

Process Flow

|

Feeding →Pleating→ Gluing → Upper & Lower Fans → Folding → Transmission → Conveyor Belt → Aluminum Rollers

|

- PP filter cartridge manufacturing

- Air filter and water filter production

- Industrial and environmental filtration equipment

- Automotive air purification systems

- Integrated automation for high production efficiency

- Precise glue control with computer synchronization

- Flexible folding adjustments for various product types

- High-quality components ensure durability and stability

- Easy operation and maintenance with intelligent control system

Bengbu Tongchen Automation Technology Co., Ltd. is a professional manufacturer specializing in filter production and automation equipment. We offer customized filtration production solutions backed by years of experience and advanced engineering technology.

Our company is dedicated to:

• Delivering innovative, efficient, and cost-effective equipment

• Providing professional technical support and after-sales service

• Ensuring high-quality materials and precision workmanship

• Helping clients enhance production efficiency and product quality

Choose Tongchen Automation — your trusted partner in intelligent filter production solutions.

Product categories

Product categories