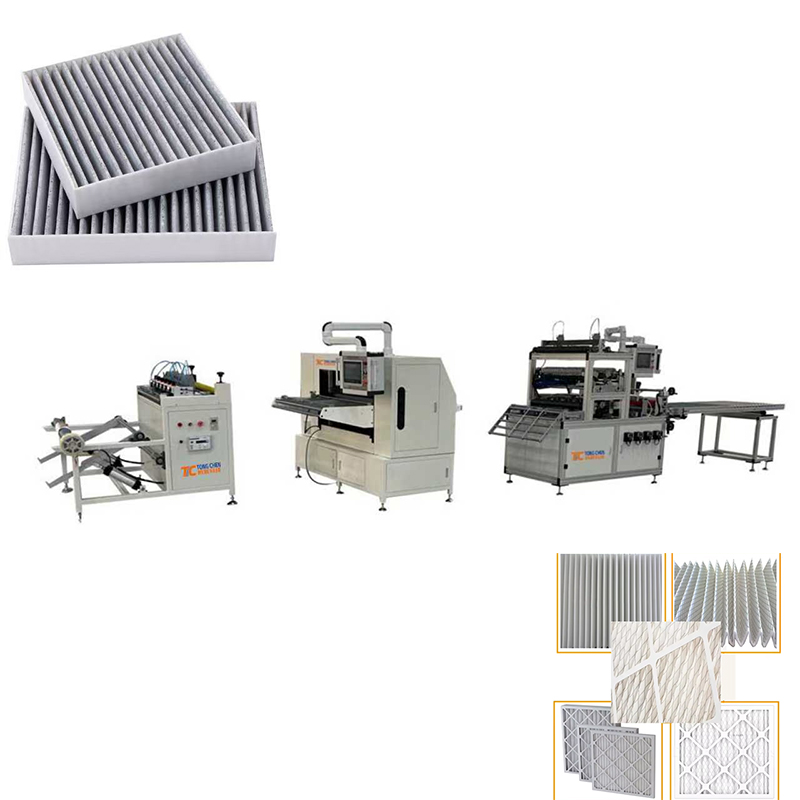

The Full-auto Servo Knife Folding and Gluing Production Line is a highly integrated core equipment tailored for filter paper processing in filter element manufacturing.With Digital Touchscreen Servo Knife Folding Gluing Equipment. Compatible with filter paper materials ranging from 25mm to 850mm in width, the production line enables adjustable folding height processing of 5mm to 70mm. Leveraging advanced technologies such as a servo control system, variable frequency speed regulation, and precise pneumatic control, it achieves full-process automation of slitting, folding, and gluing operations.

Automatic paper placement rack

Pre-slitting and paper feeding machine

Auto-counter

Filter paper folding machine

Folding and shaping

Pre-slitting & Paper Feeding Machine

|

Parameter

|

Specification

|

|

Paper feeding speed

|

0.5m/min~25m/min (adjustable)

|

|

Adjustable filter paper width

|

25~850mm

|

|

Power supply voltage

|

380V/50Hz

|

|

Motor power

|

0.55kw

|

|

Working air pressure

|

0.6Mpa

|

|

Machine weight

|

250kg

|

|

Overall dimensions

|

1280×1100×1200mm (Length×Width×Height)

|

Folding Machine

| Parameter |

Specification |

| Maximum product width |

850mm |

| Adjustable folding height range |

5~70mm (depending on materials) |

| Folding speed |

0~280 folds/min (depending on folding height) |

| Power supply voltage |

380V/50Hz |

| Motor power |

Main motor 1.8kw, lifting motor 0.4KW |

| Preheating power |

6kw |

| Temperature control range |

Room temperature~260℃ |

| Working air pressure |

0.6Mpa |

| Machine weight |

450kg |

| Overall dimensions |

1800×1500×1650mm (Length×Width×Height) |

Gluing Machine

| Parameter |

Specification |

| Maximum product width |

700mm |

| Adjustable folding height range |

6~70mm (depending on material stiffness) |

| Production speed |

4~25m/min |

| Adhesive strip spacing |

25.4mm |

| Number of adhesive strips |

2×26 strips (independently controlled by solenoid valves) |

| Power supply voltage |

380V/50HZ |

| Total machine power |

13kw |

| Working air pressure |

0.6MPa |

| Machine weight |

500kg |

| Gluing machine dimensions |

160×100×130mm (Length×Width×Height) |

| Main machine dimensions |

4000×130×160mm (Length×Width×Height) |

Pre-slitting & Paper Feeding Machine Features

- Automatic Adaptation: Equipped with automatic feeding function; both ends of the feeding roller and conveying roller are freely adjustable, easy to operate, and suitable for filter paper of different widths.

- Precise Speed Control: Adopts frequency converter for stepless speed regulation, matched with pneumatic knife for precise slitting; infrared monitoring system ensures synchronization between paper feeding speed and folding machine.

- Durable Structure: Mechanical parts adopt thickened square tubes and spray painting process; shafts are chrome-plated, with strong wear resistance.

Folding Machine Features

- Stable Feeding: The paper feeding platform is equipped with a limiting device to ensure stable input of materials of different sizes and avoid deviation.

- High-efficiency Folding: Blades are controlled by two sets of upper and lower servo motors for folding, with fast speed and high efficiency; dot counting can be precisely controlled through the display screen.

- Flexible Temperature Control: Double upper and lower heating plates (each with 3 heating discs), temperature control range from room temperature to 260℃, freely adjustable via the display screen.

- Durable Platform: The rear workbench is chrome-plated, and tempered glass is installed at the rear, combining protection and wear resistance.

Gluing Machine Features

- Intelligent Glue Control: Equipped with a 50kg hot melt glue machine and 2 sets of 26-point independent glue spraying components; 52 solenoid valves control the switch and glue volume via the touch screen.

- Multi-function Glue Spraying: Supports various modes such as continuous gluing, single-sided/double-sided gluing, intermittent gluing, staggered gluing, and fold-count gluing.

- Flexible Adaptation: The folding and wave-forming mechanism can be adjusted up and down and moved forward and backward, suitable for filter elements of various specifications and heights.

- Synchronous Control: The servo control system realizes synchronization between folding speed and conveyor belt speed, precisely controlling the spacing between papers and glue spacing.

Overall System Features

- High Integration: Integrates the entire process of slitting, folding, gluing and forming, no manual intervention in core processes, with high degree of automation.

- Intelligent Control: Core equipment is equipped with touch screens and PLC programmable controllers, with intuitive and convenient parameter adjustment and full-process digital control.

It is mainly applied in the filter element manufacturing industry, specifically designed for the folding and gluing forming processing of filter paper, the core component of various filters such as air filters, oil filters and fuel filters. Widely suitable for filter production enterprises in automotive, construction machinery, agricultural machinery, industrial equipment and other fields, it can meet the large-scale production needs of filter elements in different scenarios such as passenger cars, commercial vehicles, generator sets and air compressors.

- High-efficiency Mass Production: Folding speed up to 280 folds/min, paper feeding and gluing speeds are synchronously adapted to 0.5~25m/min, full-process continuous operation, greatly improving filter element production efficiency and meeting large-scale mass production needs.

- Precise Processing: Servo control + frequency converter stepless speed regulation + infrared monitoring, ensuring precise slitting dimensions, regular folding, uniform glue volume, strong product consistency and high qualification rate.

- Wide Adaptability: Covers 25~850mm filter paper width and 5~70mm folding height range, supports multiple gluing modes and forming adjustments, suitable for processing different types and specifications of filter elements such as air, oil and fuel filters.

- Convenient Operation:Digital Touchscreen Servo Knife Folding Gluing Equipment. 10-inch touch screen + PLC programmable control, parameter setting, counting, temperature control and other functions are one-key accessible, easy to master without complex training, reducing labor costs.

- Stable and Durable: Core components adopt high-quality brands (Huachuang servo, INOVANCE PLC, Harbin bearings, etc.), mechanical structure is strengthened, with strong wear resistance and stability, reducing equipment failure rate and maintenance costs.

- Safe and Reliable: Servo-Controlled Folding and Gluing Automation Solution.Stable working air pressure, accurate selection of electrical components, complete protection of heating and transmission systems, no potential safety hazards during operation.

Bengbu Tongchen Automation Technology Co., Ltd. specializes in the design and production of filter manufacturing equipment.

With advanced engineering and a focus on quality, Tongchen provides efficient, precise, and reliable automation solutions for the filtration industry.

Our machines are widely used in HEPA filter, automotive filter, and industrial filtration production lines, delivering proven performance and consistent results for customers worldwide.

Product categories

Product categories