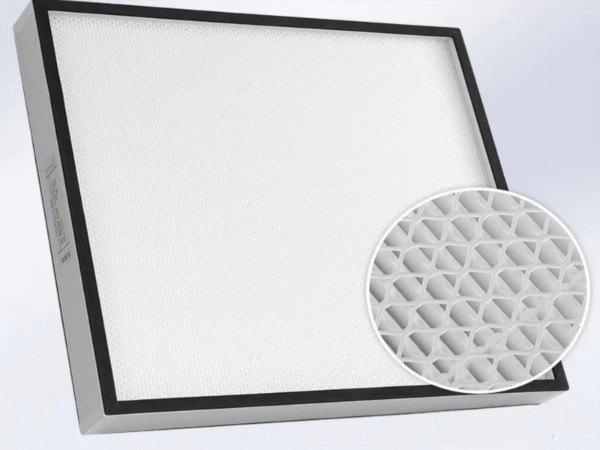

The Fully Automatic Non-Partitioned Folding and Gluing Production Line is a high-precision, fully automated system designed for continuous folding and gluing of filter materials without partition dividers.

It integrates pre-slitting, folding, hot-melt gluing, cooling, and synchronized conveying into one efficient workflow, ensuring consistent product quality and high production efficiency.

Developed for industrial air filters, automotive filters, and other pleated filtration products, this production line features intelligent control systems, servo-driven mechanisms, and adjustable folding parameters, making it suitable for diverse filter specifications.

1. High-Speed Production – Production speed adjustable between 2–15 m/min for optimized output.

2. Adjustable Folding Height – Folding height from 12 to 100 mm, controlled via touch screen.

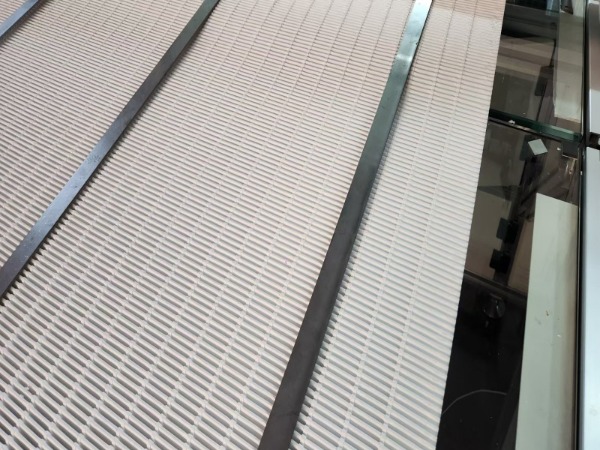

3. Precision Corrugation – Uniform corrugation spacing ensures high flatness and consistent product quality.

4. Advanced Gluing System – 50L hot-melt glue machine with dual 26-point independent glue guns, each nozzle individually controlled.

5. Flexible Glue Application – Supports continuous, single-sided, double-sided, surface-cutting, offset, and fold-count-controlled glue injection.

6. Synchronized Conveying – Servo-controlled conveyor belt ensures consistent spacing between filter materials.

7. Durable Mechanical Structure – Thickened aluminum profiles, chromium-plated shafts, and robust aluminum alloy frame provide long-term stability.

8. Intelligent Touchscreen Control – 10-inch touch screen for adjusting folding speed, glue volume, and process parameters.

|

Parameter

|

Specification

|

|

Maximum folding width

|

700 mm

|

|

Folding height

|

12 – 100 mm (adjustable via touchscreen)

|

|

Corrugation flatness

|

Uniform and consistent spacing at flat folds

|

|

Production speed

|

2 – 15 m/min

|

|

Servo motors

|

0.75 kW × 2 sets, 1.0 kW × 3 sets

|

|

High-precision reducers

|

4 sets

|

|

Hot melt glue machine capacity

|

50 L

|

|

Glue gun configuration

|

2 × 26-point independent glue spraying components with separate solenoid control

|

|

Glue line spacing

|

25.4 mm

|

|

Glue gun control

|

Touchscreen-controlled; adjustable glue volume

|

|

Glue spraying functions

|

Continuous, single-sided, double-sided, surface cutting, offset, fold-count-based injection

|

|

Power supply

|

380V / 50Hz

|

|

Total power

|

15 kW

|

|

Overall dimensions (L × W × H)

|

7000 × 1700 × 1800 mm

|

|

Glue machine preheating time

|

30 minutes

|

|

Glue line cooling

|

Multi-axis natural and fan cooling

|

|

Number of pre-slitting knives

|

2

|

|

Conveyor system

|

Servo synchronous device, adjustable paper distance

|

The production line begins by feeding filter material and performing pre-slitting using the dual knives. The material then enters the folding mechanism, where the folding height and corrugation spacing are precisely controlled by servo motors and high-precision reducers.

The hot-melt glue system applies adhesive to the pleated materials through dual 26-point glue guns, with each nozzle individually controlled via a touchscreen interface. The glue is then cooled naturally and by fans to stabilize the material.

The conveyor belt system is servo-controlled, ensuring synchronized movement of folded and glued materials while allowing precise control of spacing between each filter. All parameters, including folding speed, glue application, and conveyor synchronization, are programmable through the PLC controller, ensuring high consistency and minimal manual intervention.

|

Component

|

Specification / Brand

|

|

Servo Motors & Drivers

|

INOVANCE (Huichuan), all-digital, 3 sets

|

|

High-Precision Reducers

|

NORD, 4 sets

|

|

Touchscreen

|

10-inch, INOVANCE (Huichuan)

|

|

PLC Programmable Controller

|

Five-axis control unit with program design, INOVANCE (Huichuan)

|

|

Mechanical Parts

|

Thickened aluminum profiles, chromium-plated shafts, blackened decorative surfaces

|

|

Cylinders, Solenoid Valves, Pressure Regulators

|

Domestic brand, Harbin bearings

|

|

Folding Paper Main Machine

|

Aluminum alloy frame, tension control, creasing mechanism, transmission, pneumatic slitting, gluing, fan cooling, folding, synchronous conveyor belt

|

|

Instrument Standard Parts

|

Properly installed for easy disassembly and maintenance

|

- Air filter pleating and gluing production

- Automotive filter manufacturing

- Industrial and HVAC filter production

- High-precision filter material processing

- Fully automated workflow reduces manual labor

- Servo-controlled mechanisms ensure high precision and stability

- Touchscreen and PLC control allow flexible adjustment of folding and gluing parameters

- Multi-point glue injection ensures consistent adhesive application

- Robust mechanical construction for long-term continuous operation

- Synchronized conveyor system ensures consistent spacing and smooth material handling

Bengbu Tongchen Automation Technology Co., Ltd. specializes in designing and manufacturing advanced filter production lines. With years of experience and a commitment to innovation, we provide solutions that combine automation, precision, and high efficiency.

Benefits of choosing Tongchen Automation:

- Reliable equipment with proven industrial performance

- Flexible customization to meet various production requirements

- Comprehensive technical support and after-sales service

- High-quality components and advanced engineering ensure long service life

The Fully Automatic Non-Partitioned Folding and Gluing Production Line delivers efficient, precise, and repeatable results, making it the ideal choice for modern filter manufacturing operations.

Product categories

Product categories