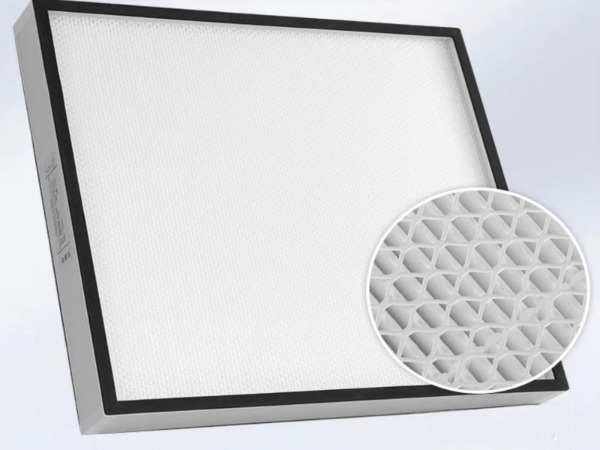

Our production line specializes in manufacturing high-temperature resistant glass fiber folded filter paper, designed for demanding industrial applications. The equipment integrates cutting-edge automation technology to ensure precision folding, uniform adhesive application, and high-speed production of filter cores used in HEPA/ULPA filters, automotive filtration, and thermal insulation systems.

|

Main components of the equipment

(1) Filter material cutting strip feeding machine

(2)Material feeding rack

(3)Pre-cutting paper feeding machine

(4) Line transportation

(5)Automatic synchronous mechanism for upper and lower lines

(6)Filter paper automatic synchronous mechanism

(7)Cutting strip tension mechanism

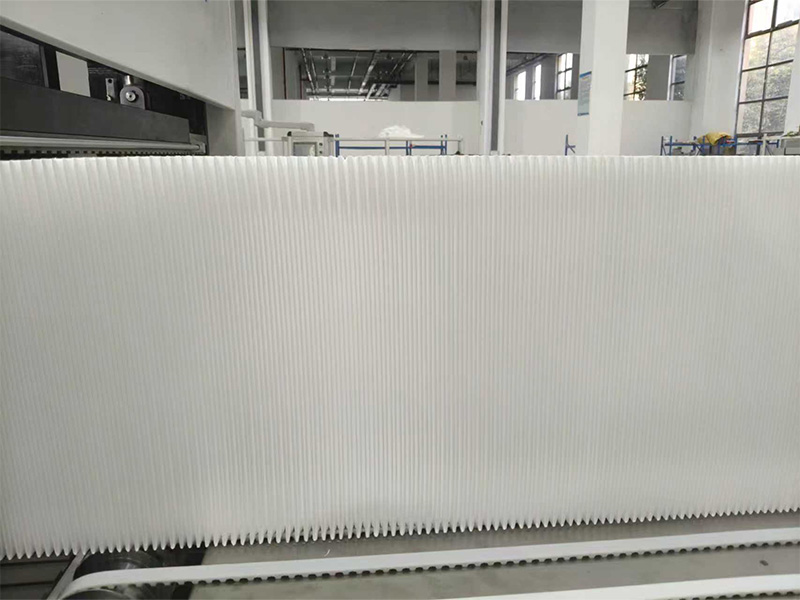

(8) Filter paper folding and shaping

|

Main functions and features

(1) Feeding function

(2) Powder brake, air expansion shaft, tension regulator, tension can be freely adjusted

(3) Feeding roller, conveying roller, both ends of the conveying roller have an adjustable cylinder

(4) Customized cutting knife

(5) Line cutting is customized according to the line width, automatic cutting of the upper and lower layers through special processing materials to control the stability of the lines

(6) Pre-cutting paper feeding machine is the latest improved cutting machine, the cutting lines adopt servo control system for synchronous movement with the folding machine

(7) Upper and lower lines and filter paper are automatically synchronous with folding

|

1. Precision & Flexibility

Multi-Layer Compatibility: Handles up to 7 layers of materials (glass fiber, PP, metal, etc.) with automatic height adjustment.

Dual-Side Processing: Simultaneous cutting and folding reduce production time by 30% compared to traditional methods.

2. Durability & Efficiency

High-Temperature Resistance: Processes glass fiber paper stable up to 500°C, ideal for industrial kilns and automotive exhaust systems.

Energy-Saving Design: Servo motors and PLC reduce power consumption by 15% (total power: 16kW).

3. Smart Automation

Touchscreen Control: Real-time parameter adjustment (speed, fold height, tension) via HMI interface.

Quick Changeover: Modular rollers and pre-set recipes minimize downtime for multi-product batches.

|

Pre-cutting Paper Feeding Machine

|

|

Folding Machine

|

|

Parameter

|

Specification

|

Parameter

|

Specification

|

|

Paper feeding speed

|

0.5m/min - 10m/min adjustable

|

Maximum product width

|

1000mm

|

|

Adjustable width

|

25 - 350mm

|

Adjustable folding height

|

20-300mm

|

|

Filter paper thickness

|

1.5mm

|

Folding speed

|

0 - 60 folds/minute (adjustable)

|

|

Power supply voltage

|

380V/50Hz

|

Glass fiber line distance

|

32mm

|

|

Motor power

|

0.55kw

|

Power supply voltage

|

380V - 50Hz

|

|

Working air pressure

|

0.6Mpa

|

Main motor power

|

4×0.75kw

|

|

Machine weight

|

250kg

|

Ascending motor power

|

0.4KW

|

|

Dimensions

|

1280×1100×1200mm (L×W×H)

|

Working air pressure

|

0.6Mpa

|

|

|

|

Machine weight

|

450kg

|

|

|

|

Dimensions

|

1800×1500×2250mm (L×W×H)

|

Custom Solutions: Tailored production lines for unique filter designs

Quality Assurance: ISO-certified manufacturing with 10+ years of industry experience.

Global Support: 24/7 technical assistance.

Product categories

Product categories