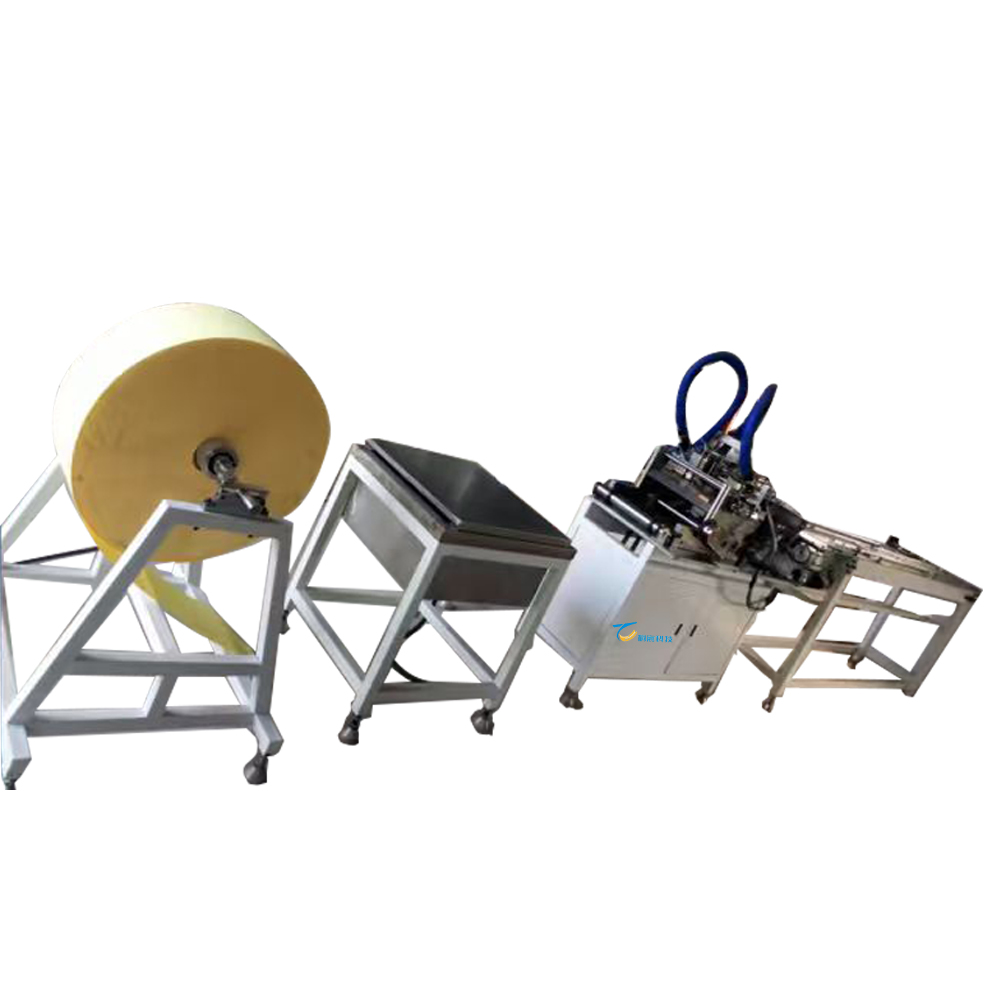

The TCPG-350 Panel Servo Paper Pleating Production Line integrates automatic feeding, humidification, imprinting, servo gluing, folding, forming, and conveyor transport. It adopts an advanced spray system to replace traditional steam heating, ensuring stable humidity and excellent fold formation.

The dual-servo glue gun system supports multiple gluing methods such as right angle, oblique angle, and double-side oblique angle. With a touch-controlled PLC system, the equipment provides easy operation, precise folding height, uniform corrugation spacing, and high-speed production ranging from 5–50 m/min.

This production line offers outstanding performance for mass production of panel-type filter paper with superior pleating quality.

Utilizes the most advanced spray system replacing traditional steam heating

Paper folding height: 20–60mm (requires roller replacement)

Corrugation flatness standard: exceptionally smooth fold height

Corrugation spacing: uniform and consistent spacing with imported roller machining technology

Two glue guns equipped with dual servo motors

PLC / touchscreen control supporting right angle, oblique angle, and double-side gluing

Guide rail adjustment system for easy operation

30-minute preheating time with timer switch

Full touchscreen control system, among China’s most advanced equipment

High-precision servo control for folding and gluing

Stable and uniform pleat formation

Adjustable folding height and width for various filter specifications

High production speed up to 50 m/min

Consistent hot melt glue application with 10L glue machine

User-friendly touchscreen interface

Reliable digital servo motors (Delta, Taiwan)

Designed for large-scale panel filter manufacturing

|

Item

|

Specification

|

|

Paper Folding Height

|

20–60 mm

|

|

Maximum Filter Paper Width

|

90–320 mm

|

|

Production Speed

|

5–50 m/min

|

|

Conveyor Belt Speed

|

0–8 m/min

|

|

Hot Melt Glue Machine Capacity

|

10L

|

|

Machine Dimensions (L×W×H)

|

6200mm × 16000mm × 1400mm

|

|

Total Power Consumption

|

9 kW

|

|

Compressed Air Supply

|

1 m³/min

|

|

Main Motor Power

|

1.1 kW

|

|

Conveyor Motor Power

|

0.55 kW

|

|

Glue Injection Servo Motor Power

|

2×400 kW

|

|

Glue Machine Power

|

6.4 kW

|

|

Machine Weight

|

600 kg

|

|

Operating Air Pressure

|

0.6 MPa

|

|

Power Supply Voltage

|

380V / 50Hz

|

Equipment Specifications: Maximum folding width 320mm

Utilizes the most advanced spray system replacing traditional steam heating

Folding height: 20–60mm (roller replacement required)

Fold flatness: exceptionally smooth

Corrugation spacing: uniform, manufactured using imported roller process

Production Speed: 5m–50m/min

Hot Melt Glue Machine Capacity: 10L

Glue Gun Performance: dual-servo motors, PLC/touchscreen control, right angle / oblique / double-side gluing

Gathering folds roller system: guide rail adjustment

Preheat Time: 30 minutes with timer switch

Full touchscreen operation

One of the most advanced pleating machines in China

Motor Configuration: Fully digital servo motors (Brand: Delta, Taiwan); three-phase motors (Brand: Huanxin, Taiwan).

Touchscreen Configuration: 7-inch touchscreen, Brand: Taiwan Weintek.

PLC Programmable Controller: Four-axis control unit, Brand: Taiwan Delta.

Frequency Inverter: Domestic brand Kerun.

Electrical Components: Custom high-precision proximity switches, imported proximity switches, relays, and small electrical parts.

Mechanical Components: Shafts with electroplated hard chrome; other components treated with standard blackening.

Glue Machine System: One 10KG glue machine, two independent glue hoses, and two glue guns.

Instrument Standard Parts: Instruments arranged logically and easy to disassemble.

Automotive panel air filters

HVAC and household air purification filters

Industrial air filtration products

Pleated filter paper for environmental and dust-removal systems

Production of flat-panel, square, and rectangular filter media

Advanced servo-driven pleating technology

Stable, uniform folding and high-speed output

Industry-leading spray humidification system

Reliable Taiwanese motor & PLC components

Flexible gluing modes with precise control

Suitable for large-scale continuous filter production

Durable structure and easy maintenance

Product categories

Product categories