This production line is ideal for automotive, air purification, water filtration, and industrial filtration industries. It is engineered for high-speed production, consistent glue application, and flexible parameter adjustment to accommodate various filter specifications.

1. Fully automatic servo-driven knife-type folding machine employs full servo and electronic cam control for folding operations.

2.Multiple angles—including upper/lower blade opening/closing angles and paper pressing angles—are freely adjustable, suitable for W-fold, step-up fold, and multi-layer material folding.

Technical Parameters of the Pre-slitting Machine

| Item |

Specification |

| Paper Feeding Speed |

0.5m/min~25m/min (adjustable)

|

| Adjustable filter paper width |

25~870mm

|

| Power supply voltage |

380V/50Hz

|

| Motor power |

0.55 kW |

| Operating air pressure |

0.6 MPa |

| Machine weight |

250 kg |

| Dimensions |

1280 × 1100 × 1200 mm (L × W × H)

|

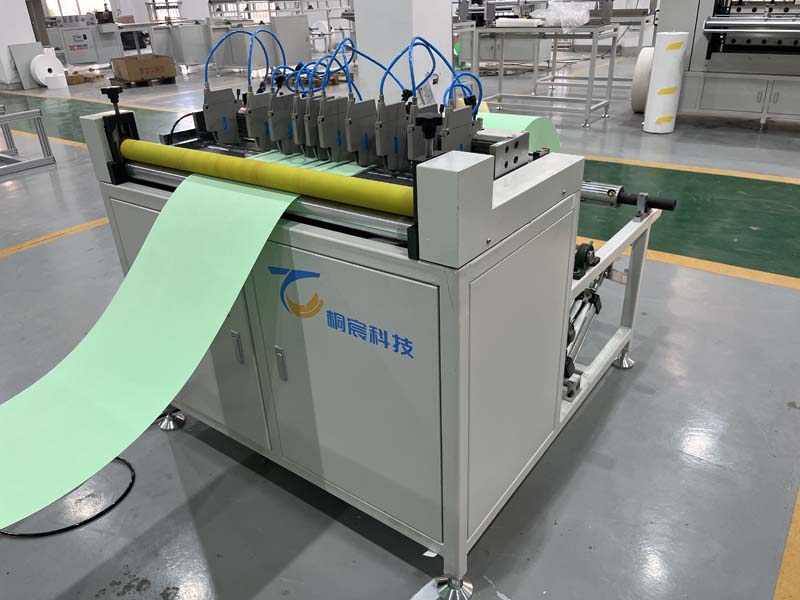

Key Functions and Features of the Pre-slitting Machine

- Automatic feeding function

- Powder brake, pneumatic shaft, tension regulator with freely adjustable tension,

- Feeding rollers, conveying rollers, each conveying roller equipped with an adjustable pneumatic cylinder at both ends for free adjustment and convenient operation,

- Six slitting blades, each blade's cutting force automatically adjustable for width,

- The pre-slitting paper feeder is the latest upgraded slitter. It can automatically and precisely adjust slitting dimensions according to different filter cartridge sizes via variable frequency drive non-polar speed control and imported pneumatic knives. Operation is convenient, slitting results are flat, and an infrared monitoring system ensures paper feeding speed matches the folder's speed.

Technical Parameters of the Pleating Machine

| Item |

Specification |

| Maximum Product Width |

870mm |

| Adjustable Fold Height Range |

5-70mm (material dependent)

|

| Folding Speed |

0-280 folds/min (non-polar adjustable)

|

| Power Supply Voltage |

380V-50Hz

|

| Main Motor Power |

1.5kW, Lift Motor: 0.4kW

|

| Preheating power |

6kW

|

| Temperature control range |

Ambient 0-260°C

|

| Operating air pressure |

0.6MPa

|

| Machine weight |

450kg

|

| Overall dimensions |

1800×1900×1650mm (L×W×H).

|

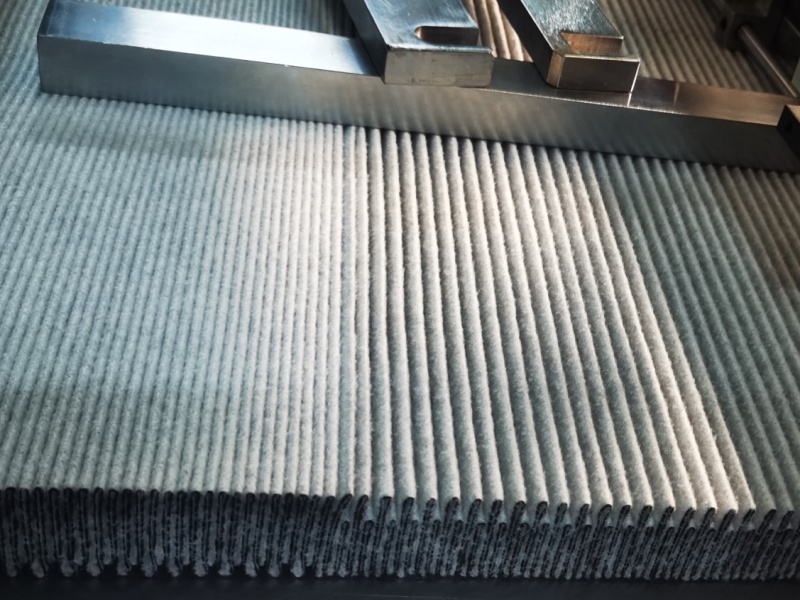

Key Functions and Features of the Pleating Machine

- Paper Feed Work Platform: Equipped with limit switches to ensure stable feeding of materials of any size without deviation.

- Punching Counting Device: Punch count can be freely controlled via the display screen.

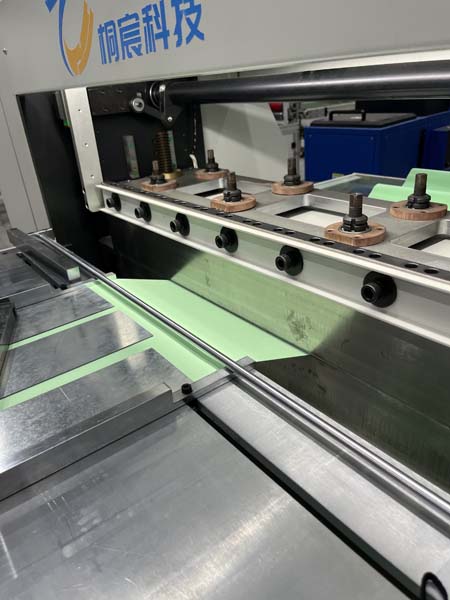

- Paper Folding Device: Folding is achieved by two servo-controlled blades each on the upper and lower sections, ensuring fast folding speed and high efficiency.

- Heating System: Heating is provided by upper and lower heating plates, each composed of three heating discs. Heating temperature is freely controlled via the display.

- Rear Work Platform: Constructed from electroplated hard chrome-treated sheet metal with tempered glass at the rear.

Pre- slitting Machine

1.Motor Configuration: Three-phase geared motor; Quantity: 1 set

2. Frequency Converter: Brand: Domestic brand; Quantity: 1 set

4. Mechanical Components: Reinforced aluminum alloy frame, stainless steel door panels, shafts with electroplated hard chrome finish, other parts with decorative black oxide finish;

5. Brand: Cylinders, Solenoid Valves, Pressure Regulators: Domestic Brand; Bearings: Domestic Brand

6. Slitting Main Unit: Includes automatic feeding, pneumatic shaft, powder brake, tension regulator, feed workbench, slitting device, conveyor rollers, infrared monitoring

7. Instrument Standard Parts Configuration: All instruments installed reasonably and easily removable

Pleating Machine

1 Motor Configuration: Fully digital servo motors and drives, Brand: INOVANCE (Huichuan), Quantity: 5 sets

2. Touchscreen Configuration: 10-inch touchscreen, Brand: INOVANCE (Huichuan)

3. PLC Programmable Controller Configuration: Five-axis control unit (includes programming engineering), Brand: INOVANCE (Huichuan)

4. Mechanical Components: Reinforced aluminum alloy frame, stainless steel door panels, shafts with electroplated hard chrome plating, other parts with decorative black oxide finish;

5. Cylinders, Solenoid Valves, Pressure Regulators: Domestic brands, Harbin Bearings

6. Folding Machine Main Unit: Includes paper feed, feed workbench, upper/lower blade folding forming, heating setting, output workbench, pneumatic paper output stabilization

7. Instrument Standard Parts Configuration: All instruments installed rationally for easy disassembly

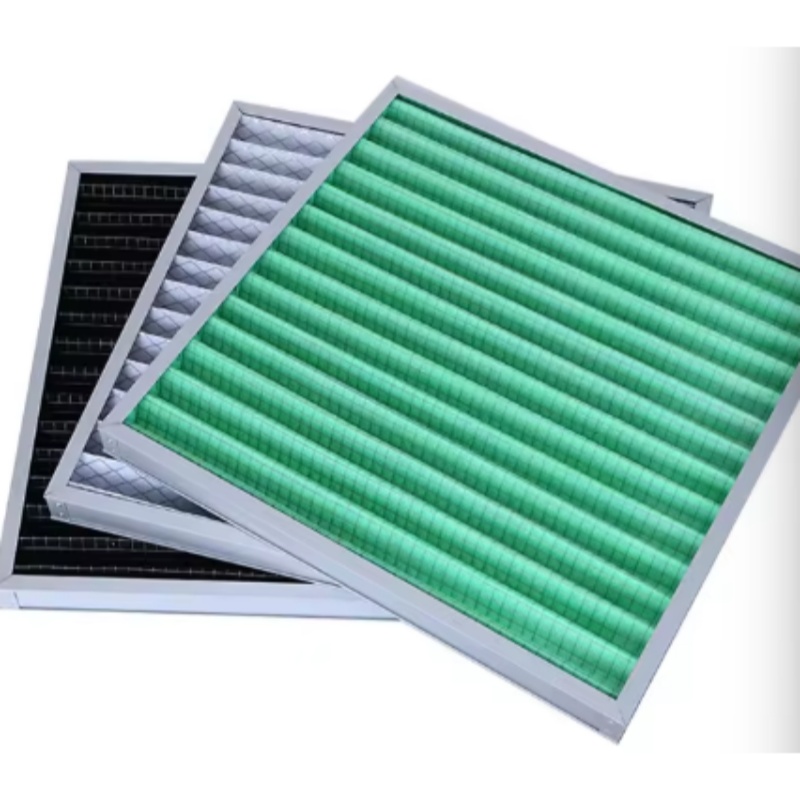

- PP filter cartridge manufacturing

- Air filter and water filter production

- Industrial and environmental filtration equipment

- Automotive air purification systems

- Integrated automation for high production efficiency

- Precise glue control with computer synchronization

- Flexible folding adjustments for various product types

- High-quality components ensure durability and stability

- Easy operation and maintenance with intelligent control system

Bengbu Tongchen Automation Technology Co., Ltd. is a professional manufacturer specializing in filter production and automation equipment. We offer customized filtration production solutions backed by years of experience and advanced engineering technology.

Our company is dedicated to:

• Delivering innovative, efficient, and cost-effective equipment

• Providing professional technical support and after-sales service

• Ensuring high-quality materials and precision workmanship

• Helping clients enhance production efficiency and product quality

Choose Tongchen Automation — your trusted partner in intelligent filter production solutions.

Product categories

Product categories