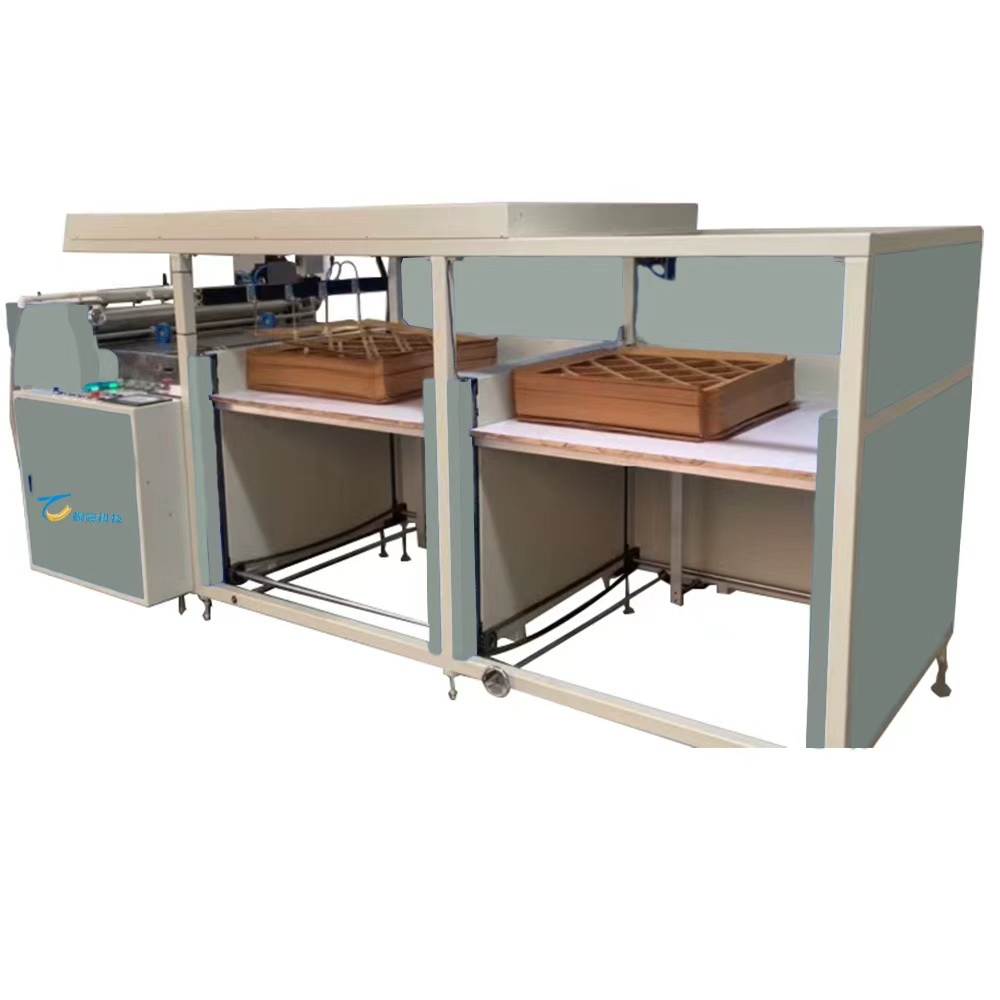

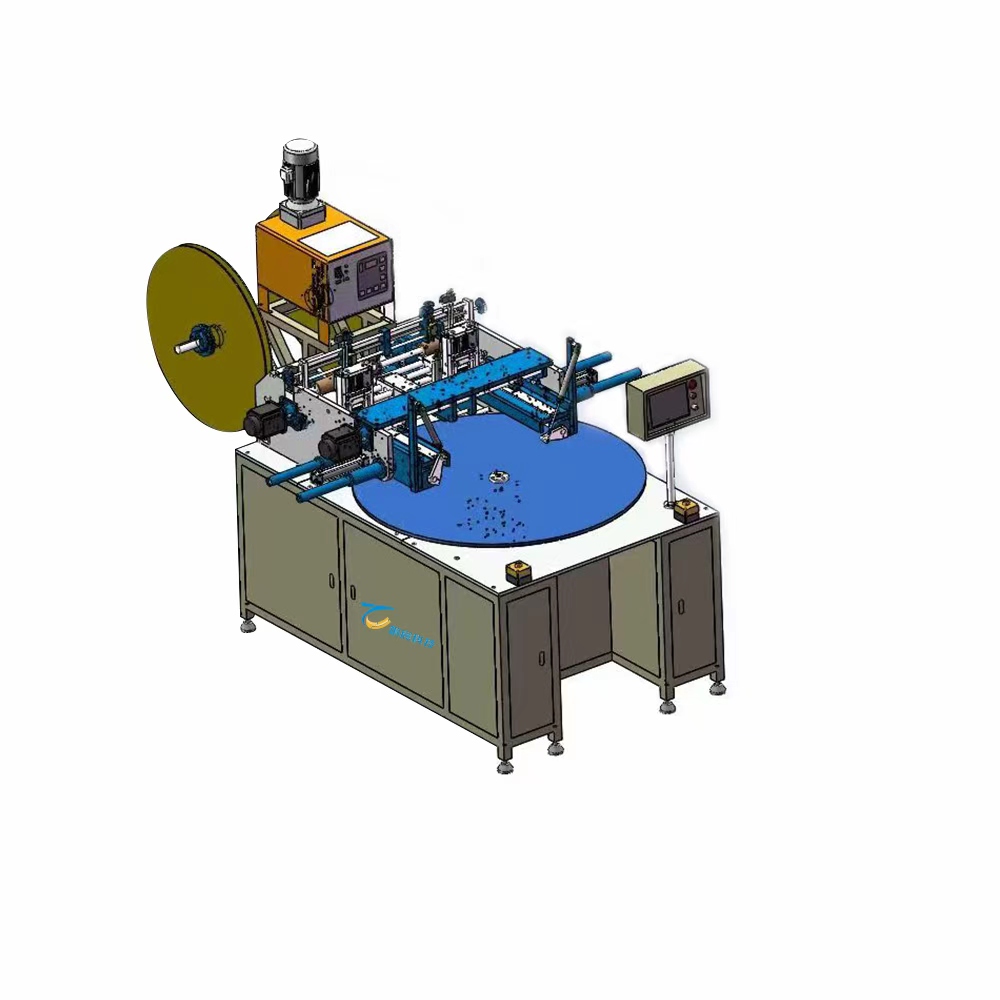

Built with a durable carbon-steel structure and equipped with Mitsubishi PLC and Weintek touchscreen controls, this machine delivers advanced real-time mixing, intelligent monitoring, and automated cleaning capabilities. Its dual-bucket storage system prevents adhesive solidification, while adjustable mixing ratios from 10:1 to 10:10 ensure compatibility with different glue formulations. With features such as anti-solidifying programs, alarm protection, weighing-assisted ratio adjustment, and precise digital dispensing control, the Filter Semi-automatic Injecting Glue Machine offers manufacturers a reliable, efficient, and stable solution for accurate glue dispensing in filter assembly and other industrial production lines.

-

Precise Adjustable Dispensing

Glue output size, dispensing time, and ratio can be adjusted via digital parameters, ensuring accurate dispensing without dripping or leakage.

-

On-Demand Mixing & Maximum Glue Savings

Real-time ratio adjustment enables simultaneous mixing and dispensing, minimizing adhesive waste and improving cost efficiency.

-

Dual-Bucket Storage System

Separate 30L heated A/B buckets prevent premature curing and ensure stable adhesive properties during long-term storage.

-

Wide Ratio Range with Static Mixing

Adjustable mixing ratio from 10:1 to 10:10 with static mixing valves ensures uniform and thorough blending.

-

Comprehensive Alarm System

Includes low air-pressure alarm, material shortage/full alarm, contamination alarm, and abnormal fault warnings.

-

Automatic Liquid Level Detection

Buckets equipped with level switches provide automatic shortage/full alarms and machine auto-stop protection.

-

Smart Monitoring & Productivity Tracking

Features yield counting, individual piece timing, and operational monitoring with alarm alerts.

-

Advanced Auto-clean Functions

Multiple cleaning modes for different adhesive types, plus one-touch auto-cleaning of mixing tubes and valves.

-

Anti-solidifying Program

Prevents adhesive curing inside pipes and valves during temporary stops.

-

Built-in Weighing System

Unique weighing function simplifies ratio adjustments and enhances precision.

-

Digital Speed Control

Electronic dispensing-speed control allows easy fine-tuning of adhesive output volume.

-

High dispensing accuracy with ±2% error

-

Supports a wide range of adhesives and mix ratios

-

Reduced material waste through real-time ratio mixing

-

Stable, durable carbon steel painted structure

-

Intelligent system with Mitsubishi PLC + Weintek HMI

-

Safe operation with complete protection and alarm systems

-

Easy maintenance with automatic cleaning modes

-

Continuous operation without solidification issues

-

Efficient for batch and continuous production lines

-

Ideal for filter manufacturing, improving efficiency and consistency

| Item |

Specification |

| Structure |

Carbon steel painted structure |

| Control System |

Self-R&D program; Mitsubishi PLC + Weintek touchscreen |

| Stock Buckets |

A: 30L carbon steel with heating; B: 30L carbon steel with heating; both with heating funcion,feeding funnel, inspection glass, full/empty alarms |

| Mixing Scale |

Main scale 2:1 (adjustable); overall 10:1–10:10 adjustable; digital input |

| Measuring Pump |

A pump: 6CC gear pump; B pump: 3CC gear pump |

| Glue Supply System |

Leisa stepper motor/driver + gear pump |

| Discharging Method |

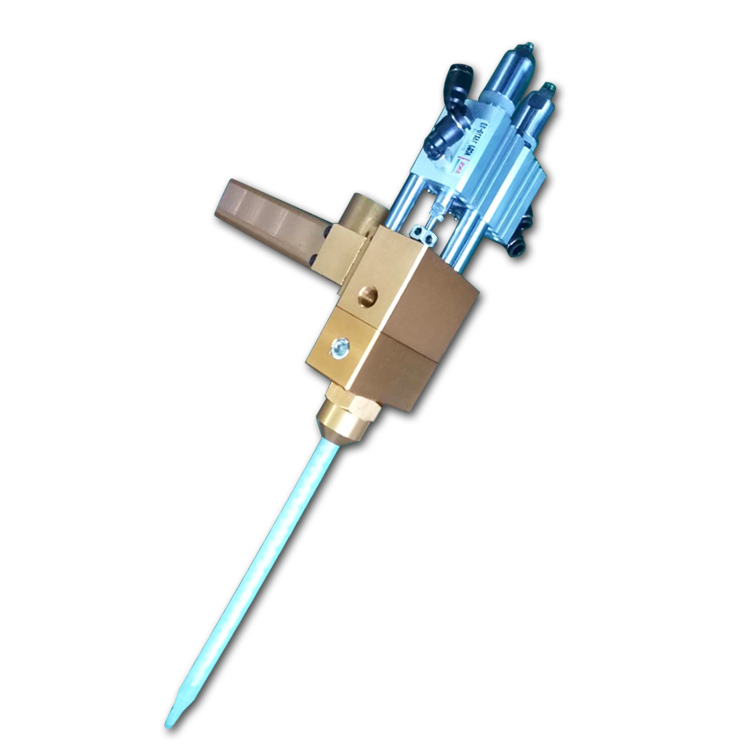

Static mixing valve discharge |

| Air Pressure Requirement |

0.5–0.7 MPa |

| Power Supply |

220V / 50Hz |

| Discharge Speed |

1–25 g/s |

| Discharge Accuracy |

±2% |

| Programs & Functions |

One-touch cleaning; timed/metered dispensing; anti-solidifying; low-pressure alarm; abnormal fault alarm |

| Monitoring Features |

Output counting; timing; operational supervision alarms |

-

Filter manufacturing (air filters, oil filters, industrial filtration products)

-

Automotive filter assembly lines

-

HVAC purification equipment production

-

Adhesive bonding for dual-component glues

-

Electronics potting & sealing processes

-

Plastic parts & hardware bonding

-

Industrial and small-to-medium production operations requiring precise dispensing

-

Professional R&D Capability: Self-developed glue-control system ensures higher stability and accuracy.

-

Industrial-Grade Components: Mitsubishi PLC and Weintek HMI guarantee reliability and long service life.

-

High Efficiency & Low Maintenance: Smart cleaning, anti-clogging system, and stable dispensing performance.

-

Strong Adaptability: Compatible with various AB adhesives and production line requirements.

-

Enhanced Safety & Protection: Full alarm system reduces equipment downtime and protects production stability.

-

Cost-Effective Operation: Minimizes glue waste while maintaining precise ratio control.

-

Proven in the Filtration Industry: Optimized for filter manufacturing with long-term field application success.

Product categories

Product categories