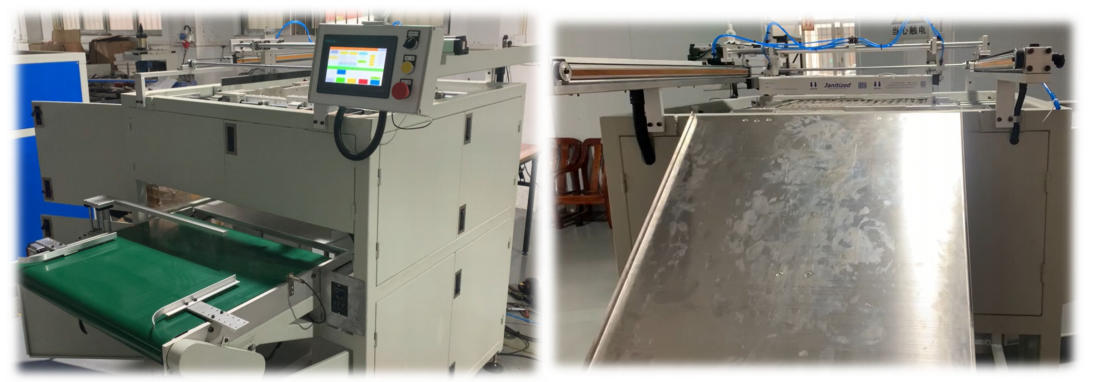

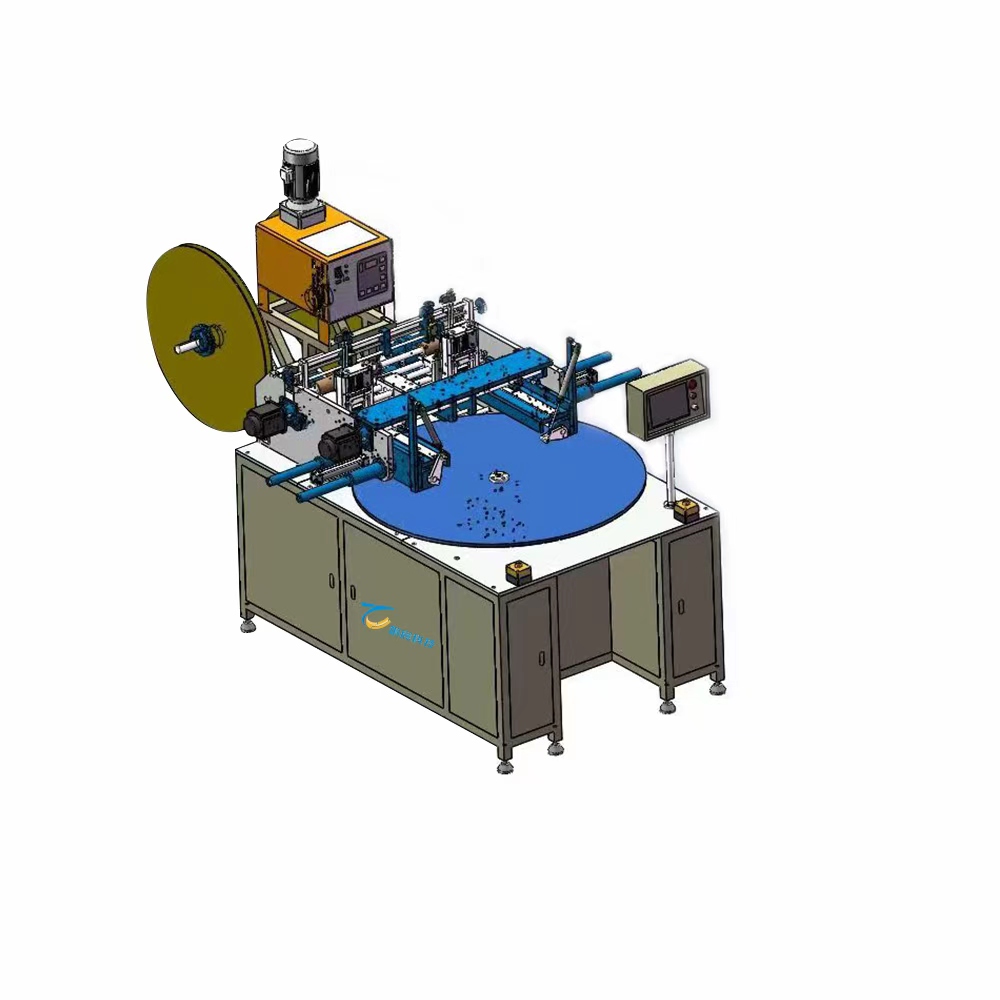

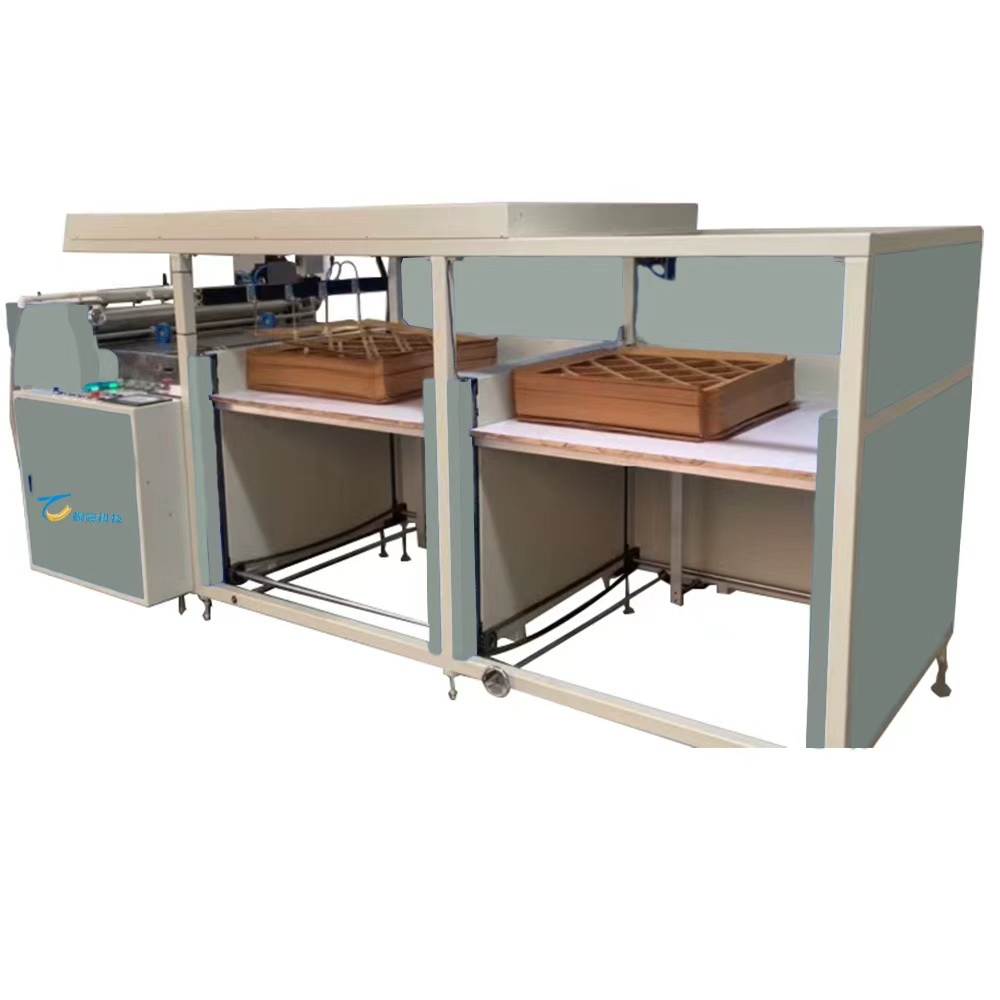

Paper Frame Filter Setting Machine

This machine ensures tight adhesion and correct positioning of all edges, producing a semi-dry adhesive surface to prevent joints from popping off, guaranteeing a fully bonded product.

The equipment supports adjustable sizes, adaptive paper frame types, and offers a reliable solution for high-efficiency filter production.

-

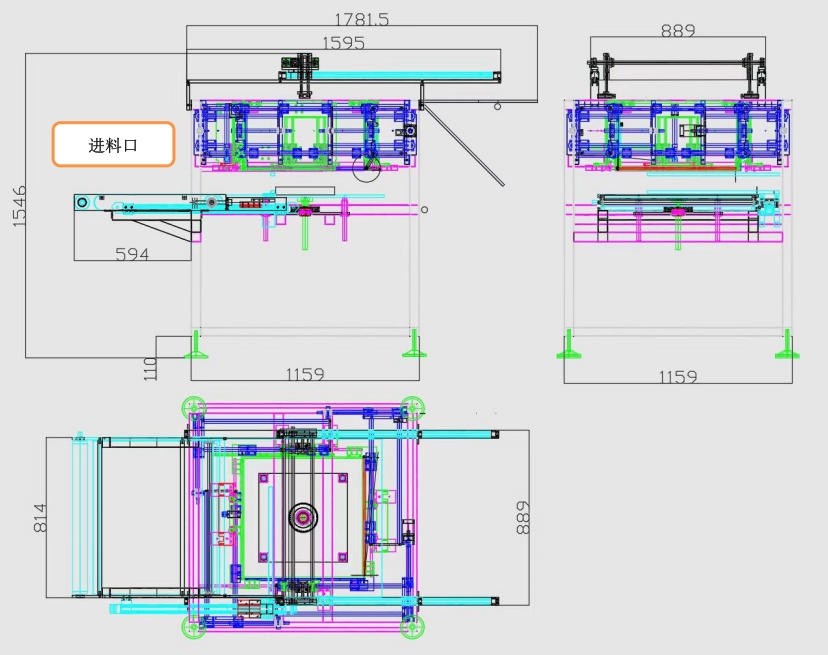

Width and height adjustable via servo motor, automatic parameter adjustment

-

Automatic product loading on feeding bench

-

Adjustable lifting speed

-

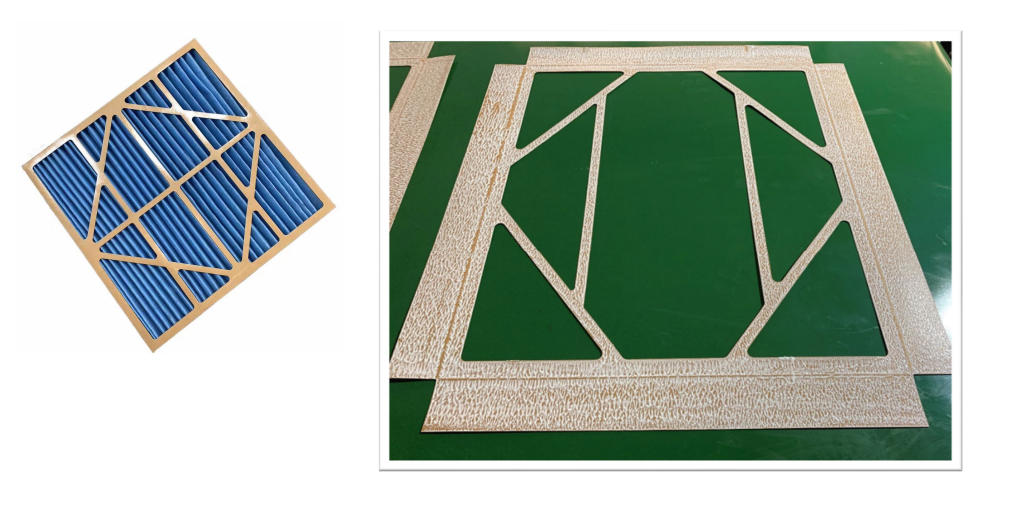

Compatible with various paper frame materials (laminated, standard)

-

Adaptive upper-lower type paper frame

-

Operating indicator light for real-time status

-

Automatic material pushing and ejecting device

-

Alarm display for immediate issue identification

-

Heat temperature adjustable from 20–90°C ±3°C

-

High processing efficiency: ≤15 seconds per piece

-

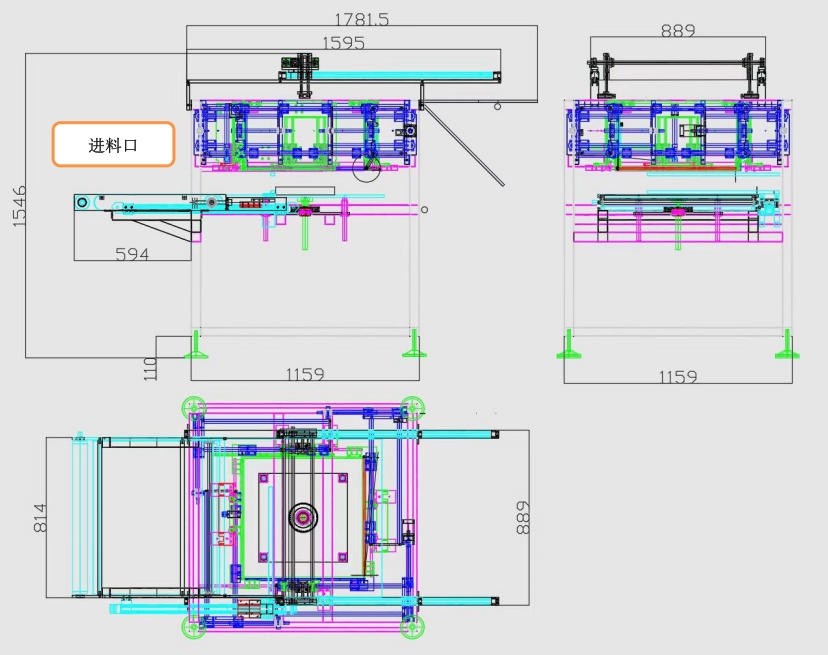

Compatible with 285–592mm width, 30–100mm height, double paper frame

-

Wall panel fixing size: 300mm

-

Feeding bench: 600×500mm, motor-driven pushing plate

-

Discharging via motor-controlled clamp and cylinder lifting/conveying

-

Power supply: 220VAC, Motor power: 4.5kW

-

Air pressure requirement: 0.4–0.6MPa

| Parameter |

Specification |

| Size |

300–600mm (Non-standard: 340–680mm, +100mm in length & width) |

| Adjustable Position |

Width & Height via servo motor |

| Feeding Bench |

600×500mm, motor and pushing plate |

| Discharging Method |

Clamp location controlled by motor; lifting/conveying by cylinder (left & right sets) |

| Power Voltage |

220VAC |

| Motor Power |

4.5kW |

| Air Pressure |

0.4–0.6MPa |

| Heat Temperature |

20–90°C ±3°C |

| Processing Efficiency |

≤15 seconds/piece |

| Adaptive Paper Frame |

Upper-lower type, laminated/standard materials |

| Wall Panel Fixing Size |

300mm |

-

Manual pre-assembly with glued paper frame

-

Place product on conveyor

-

Automatic push-in and positioning

-

Complete shaping process

-

Remove product and slide it to acceptable conveyor

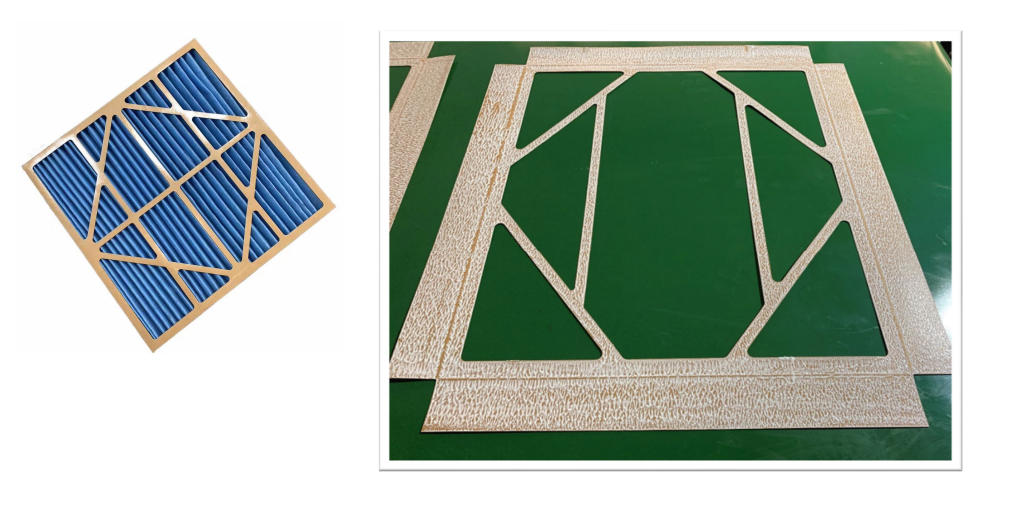

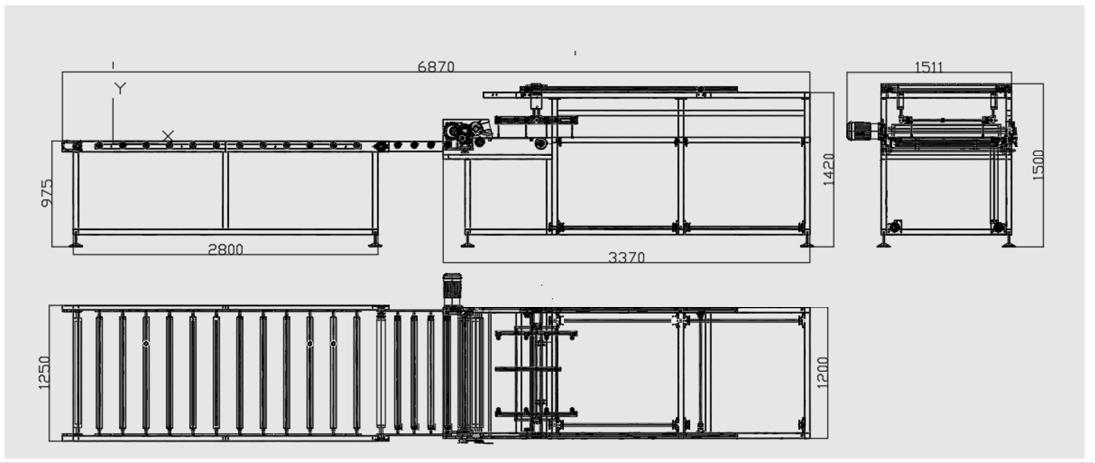

Paper Frame Filter Gluing Machine

The Paper Frame Filter Gluing Machine automates the adhesive application process for paper frame filters. By combining precision feeding with adjustable glue rollers, it ensures consistent glue coverage across various sizes and thicknesses. This machine reduces manual labor, improves production speed, and provides uniform adhesive results, making it an essential tool for modern filter manufacturing.

-

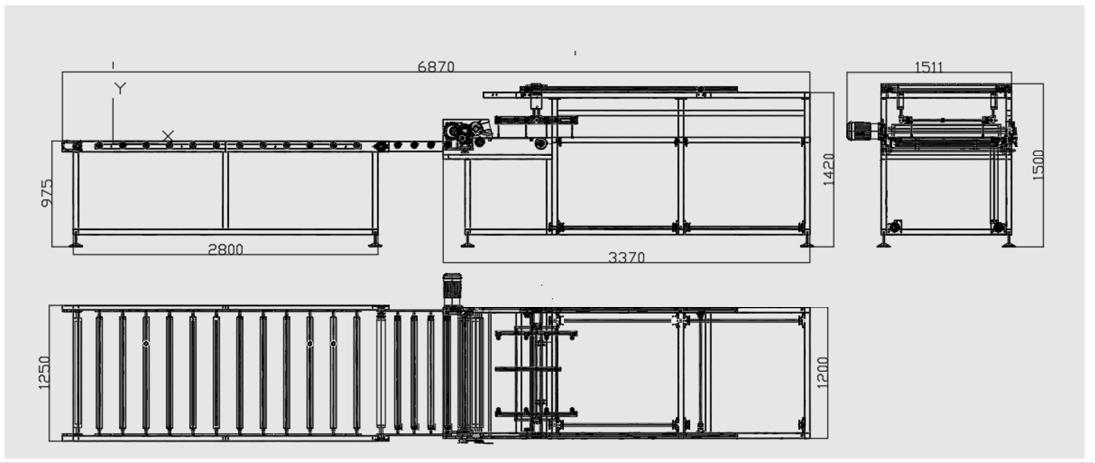

Adaptive paper frame size: 280×280–900×900mm

-

Compatible with paper frame thickness: 0.5–2mm

-

Production speed: 20 sec per set (1 set = bottom lid + upper lid)

-

White emulsion glue suitable for strong adhesion

-

Automatic glue application via circulating glue pump

-

Air-driven suction feeding for precise handling

-

Manual glue cleaning for convenience

-

Sturdy metal iron frame with baked finish

-

Conveyor and feeding bench compatible with large-scale production

-

High efficiency: reduces manual handling and speeds up production

-

Adjustable glue thickness for different filter requirements

-

Stable and precise feeding system ensures uniform glue application

-

Flexible size adaptability supports multiple paper frame specifications

-

Durable construction ensures long-term industrial use

-

Semi-automatic operation balances automation and operator control

| Parameter |

Specification |

| Adaptive Paper Frame Size |

280×280–900×900mm |

| Adaptive Paper Frame Thickness |

0.5–2mm |

| Production Speed |

20 sec/set (1 set = bottom lid + upper lid) |

| Glue Type |

White emulsion |

| Glue Application |

Circulating glue pump |

| Glue Cleaning |

Manual cleaning |

| Equipment Dimension |

3400×1730×1500mm (L×W×H, without conveyor) |

| Conveyor Dimension |

2500×1240×950mm (L×W×H) |

| Feeding Bench Dimension |

1000×1000mm, loading 500 sets of 1.2mm paper frames |

| Material |

Metal iron frame, baked finish |

| Power Supply |

3ɸ380VAC + N |

| Air Pressure |

0.6–0.7MPa |

-

Panel-type primary paper frame filter production

-

Air conditioning and HVAC filter manufacturing

-

Industrial filtration system production

-

Laboratories and cleanroom filter assembly

Gluing Machine Operation Process

-

Manually stack the paper frames on the feeding platform

-

Add glue into the glue bucket

-

Start the equipment for automatic feeding and glue application

-

Paper frames are transferred to the production line

-

Manually take out the paper frames

-

Reliable automation for consistent glue application

-

Supports multiple paper frame sizes and thicknesses

-

Durable and high-quality metal construction

-

Improves production efficiency and reduces manual errors

-

User-friendly operation with easy maintenance

Product categories

Product categories