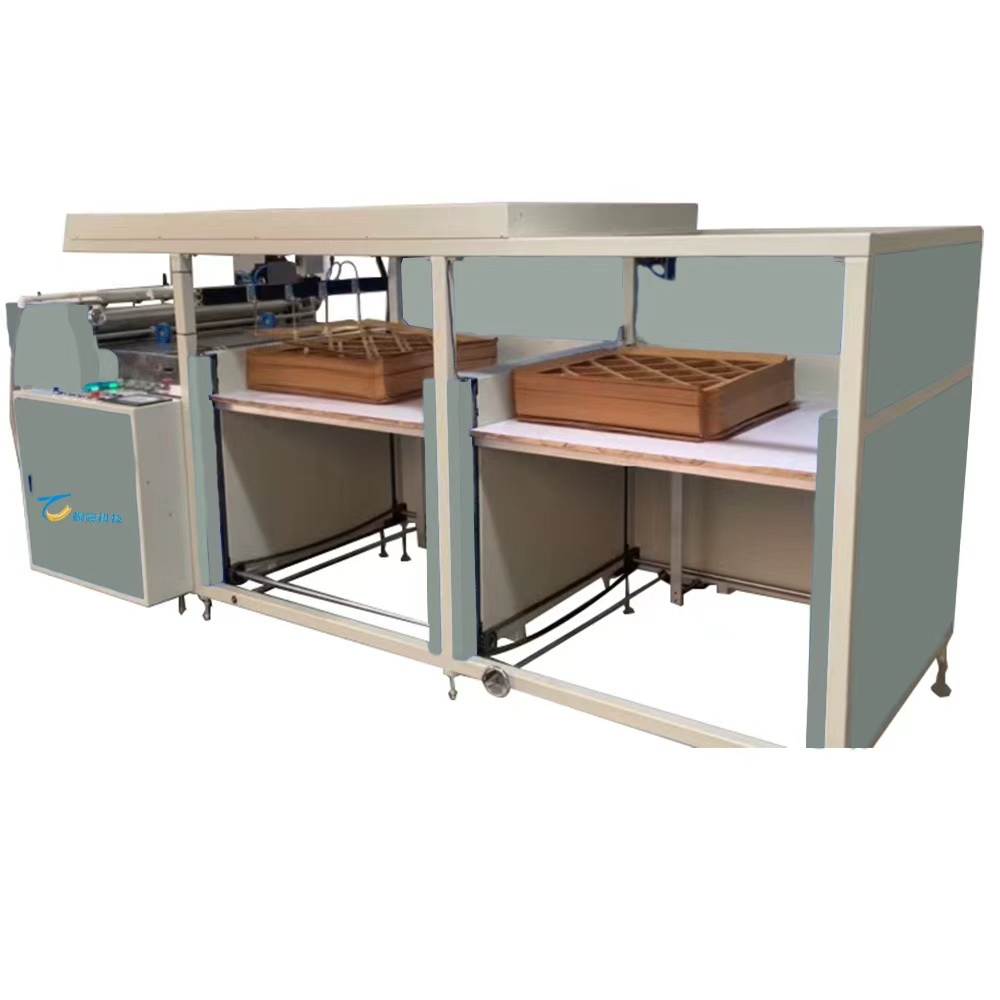

The Fully Automatic Continuous Edge-Gluing Machine is a high-performance automated edge sealing system engineered for air filters, industrial panels, and multi-layer materials requiring consistent edge banding. Featuring a complete servo system, synchronous conveyor belt technology, and a 30L hot melt glue unit, the equipment achieves precise glue application with minimal manual involvement.

With intelligent cutting, automatic cooling, and uniform glue-coating control, this production line significantly enhances productivity while ensuring energy efficiency and stable performance.

-

Dual-side automatic edge gluing with synchronous belt transport

-

30L high-capacity hot melt glue machine for long continuous operation

-

Servo-driven automatic edge strip cutting for precise length control

-

Adjustable glue-coating width (13–65 mm) for various filter sizes

-

Automatic cooling system for stable glue solidification

-

High-speed output up to 5 m/min

-

10-inch touchscreen control with intuitive parameter settings

-

Full INOVANCE servo system ensuring consistent accuracy

-

Reinforced structural design with chrome-plated shafts and black-oxide treatment

-

Energy-efficient operation with uniform adhesive thickness

-

Fully automated process reduces labor costs

-

High bonding consistency due to precise servo control

-

Fast and stable production with 15 kW power configuration

-

Long-term durability using high-grade aluminum/iron structural profiles

-

Easy setup & operation through the PLC-controlled touchscreen

-

Clean and uniform adhesive application with adjustable coating width

-

Low maintenance thanks to accessible mechanical and electrical layouts

-

Ideal for mass production, improving speed and accuracy simultaneously

Performance Parameters

| Item |

Specification |

| Max Folding Width |

100–500 mm |

| Production Speed |

1–5 m/min |

| Servo Motor Power |

0.75 kW × 3 |

| Additional Servo Motor |

0.4 kW × 1 |

| Glue-Coating Width |

13–65 mm (adjustable) |

| Edge Strip Width |

12–70 mm |

| Hot Melt Glue Tank Capacity |

30 L |

| Power Supply |

380V / 50Hz |

| Total Power |

15 kW |

| Dimensions |

6000 × 2000 × 1800 mm |

| Glue Preheating Time |

30 minutes |

| Cooling Method |

Automatic cooling |

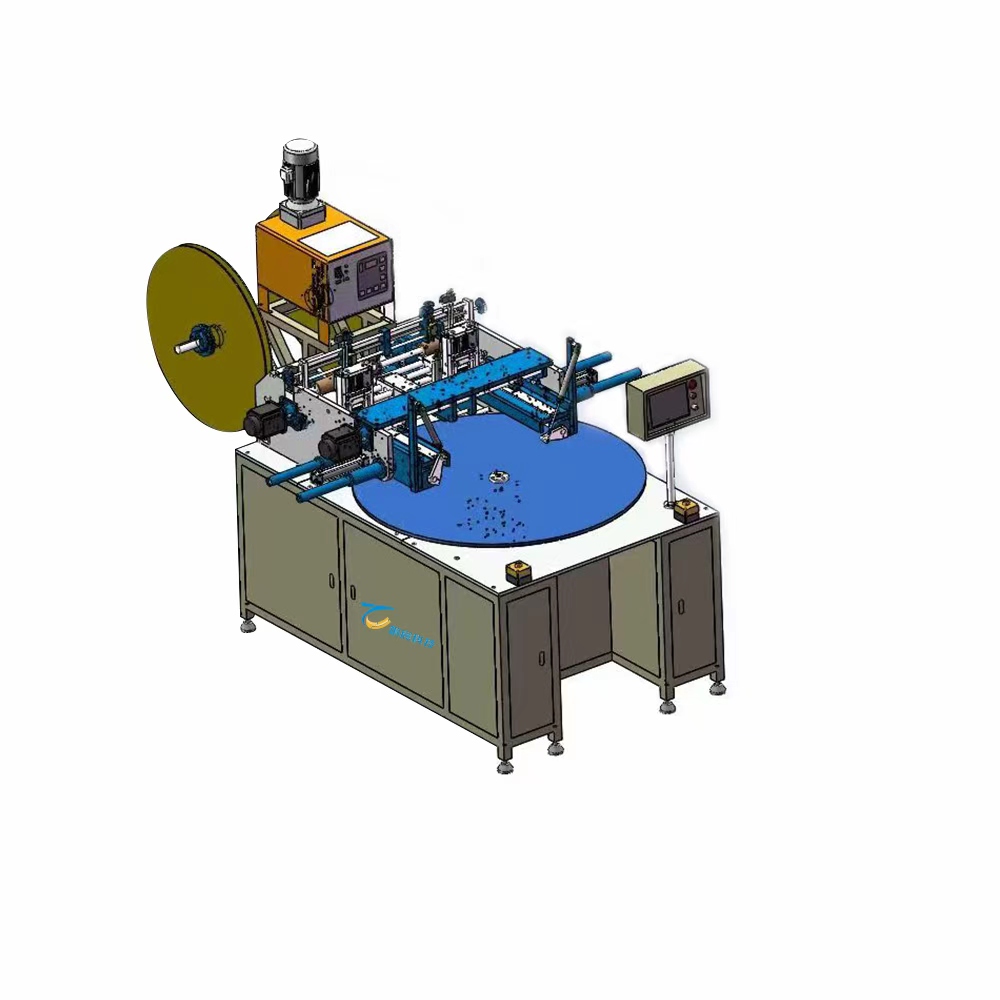

Configuration List

| Component |

Specification |

| Servo Motors & Drives |

INOVANCE (4 sets) |

| High-Precision Reducer |

NUSTA |

| Control Interface |

10-inch INOVANCE touchscreen |

| PLC System |

INOVANCE five-axis programmable controller |

| Mechanical Structure |

Reinforced aluminum/iron, chrome-plated shafts, black oxide finishing |

| Pneumatic Components |

Domestic cylinders, solenoid valves, pressure regulators |

| Bearings |

Harbin Bearings |

| Glue Application System |

30L hot melt glue machine + 2 scraping units |

This machine is ideal for industries requiring precise continuous edge gluing, including:

-

Air filter manufacturing (primary, medium, high-efficiency filters)

-

Automotive filter edge sealing

-

Industrial panel edge banding

-

Household appliance filter production

-

HEPA and HVAC filter production lines

-

Composite material bonding

-

Packaging and insulation materials

-

Edge sealing for multilayer paper and nonwoven materials

Perfect for factories specializing in filtration, environmental equipment, automotive components, and automated assembly lines.

-

Expert manufacturer with extensive automation experience

-

Full-servo architecture ensures accuracy and stability

-

Industrial-grade durability with premium mechanical construction

-

Clear and simple operation via touchscreen interface

-

Customizable design for width, glue type, and production requirements

-

Fast delivery and strong technical support

-

Cost-effective and high-performance for mass production operations

-

Reliable parts from reputable brands like INOVANCE and NUSTA

Product categories

Product categories