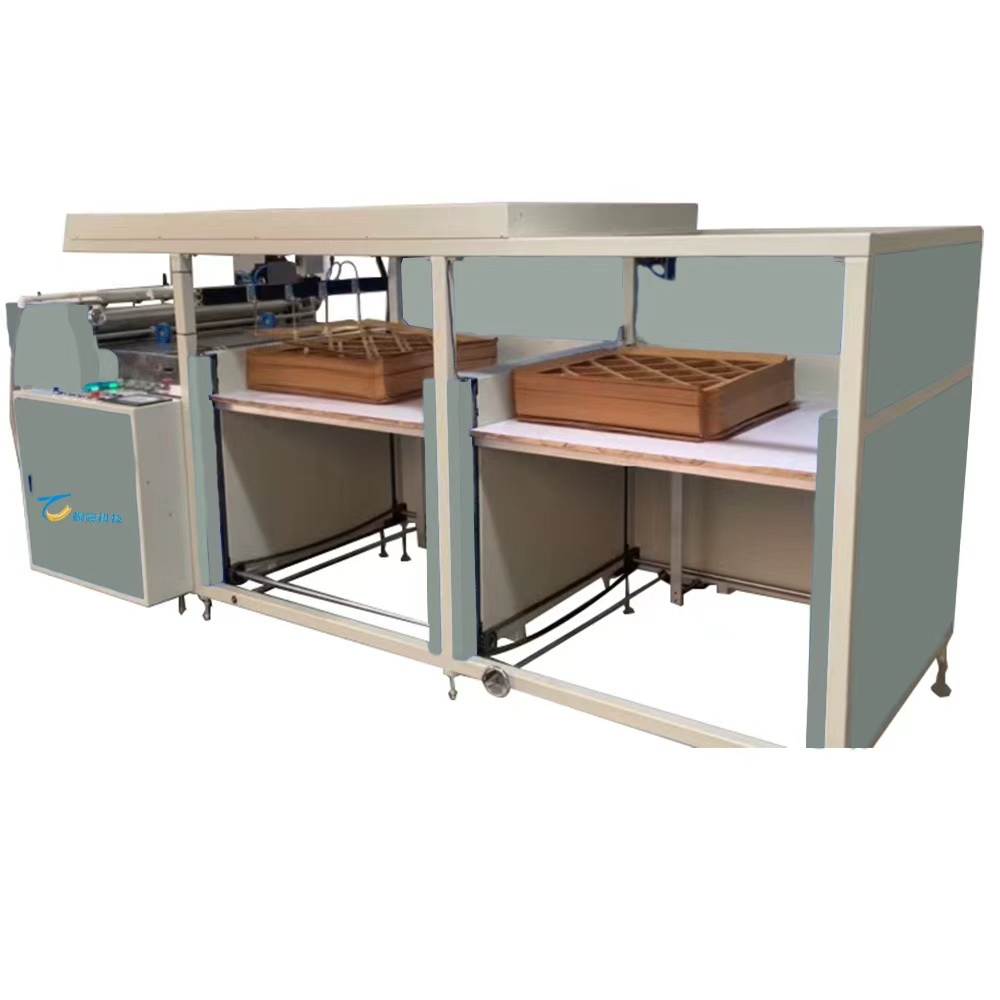

The Full-Auto Cabin Air Filter Side-Gluing Machine is a state-of-the-art solution designed for high-efficiency and precise side-edge bonding of cabin air filter elements. This servo-driven system automates the critical processes of adhesive application and filter cutting, ensuring uniform glue thickness and consistent product length. By utilizing advanced spiral wheel spacing control, it eliminates the need for traditional molds, significantly reducing material waste and labor costs. Experience superior production quality and energy efficiency for your air filter manufacturing line.

Main Features & Advantages

Fully Automatic and Precise Gluing:

The equipment performs automatic edge coating on both sides of the product. The innovative spiral wheel control manages pleat spacing, replacing material-wasting molds and minimizing manual labor.

High Efficiency & Energy Saving:

Features a servo-driven automatic cutting system. Operators simply set the desired product length on the 7-inch touchscreen, and the PLC automatically executes precise, clean cuts.

Superior Control System:

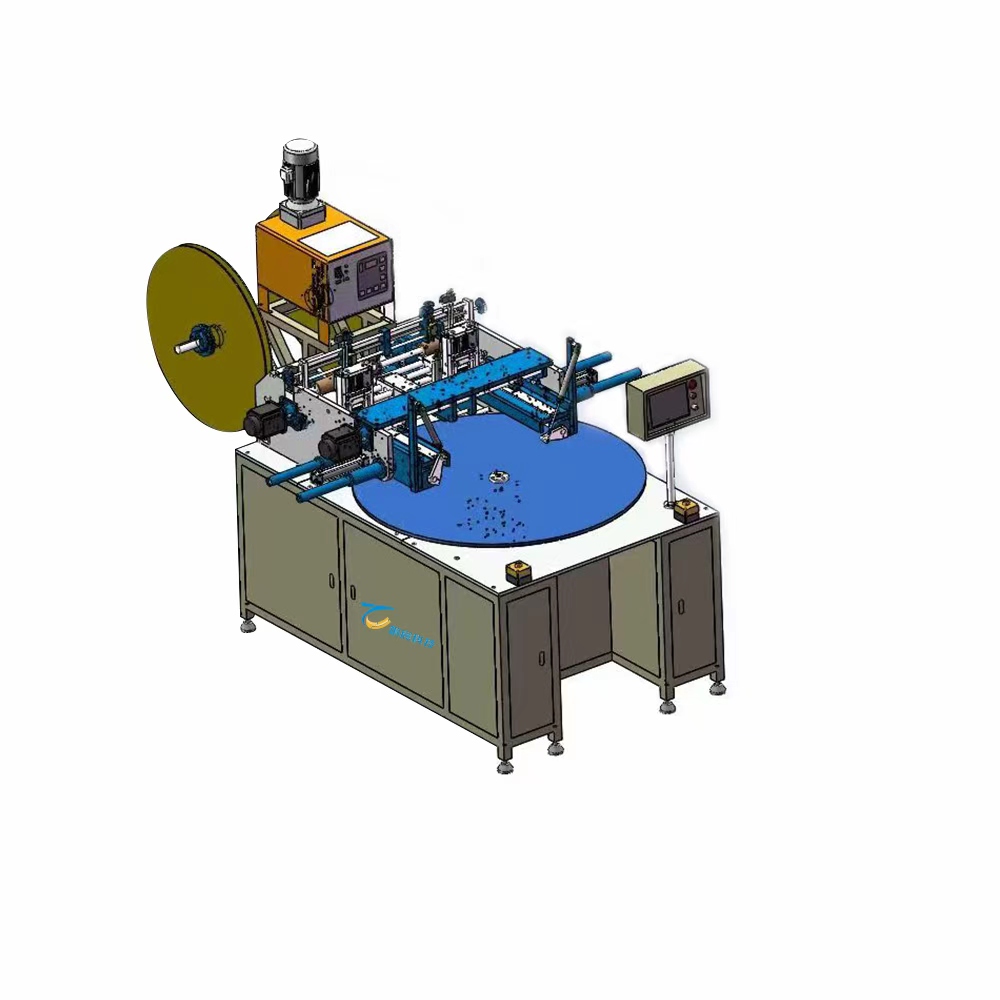

Equipped with four sets of INOVANCE (Huichuan) fully digital servo motors, drives, and a 5-axis PLC control unit, ensuring stable, high-speed, and accurate operation.

Uniform Adhesive Application:

Utilizes a robust 30L hot melt adhesive tank and a dual scraping system for consistent and adjustable glue width (10-50mm).

Durable and Heavy-Duty Construction:

Mechanical components are built with heavy-duty aluminum/iron profiles, hard chrome-plated shafts, and decorative black oxide finished parts for longevity and reliability.

| Parameter |

Specification |

Unit |

| Max. Pleat Width |

150−300 |

mm |

| Filter Pleat Height |

20−45 |

mm |

| Production Speed |

4−5 |

pleats/s |

| Total Servo Motors |

4 sets (3×0.75kW+1×0.75kW) |

kW |

| Edge Strip Adhesive Width |

10−50 (Adjustable) |

mm |

| Hot Melt Adhesive Capacity |

30 |

L |

| Edge Strip Width |

20−60 |

mm |

| Power Supply |

380V/50Hz |

|

| Total Power |

15 |

KW |

| Overall Dimensions (L×W×H) |

6000×2000×1800 |

mm |

| Glue Machine Preheat Time |

30 |

minutes |

| Glue Line Cooling Method |

Automatic Cooling |

| Control System Brand |

INOVANCE (Huichuan) |

| Reducer Brand |

NUSTA |

| Component Type |

Brand/Specification |

Quantity |

| Servo Motors & Drives |

INOVANCE (Huichuan), Fully Digital |

4 sets |

| PLC Controller |

INOVANCE (Huichuan), 5-axis Control Unit |

|

| Touchscreen |

INOVANCE (Huichuan), 7-inch |

|

| High-Precision Reducer |

NUSTA |

|

| Glue Application System |

1×30L Hot Melt Glue Machine, 2× Scraping Systems |

|

| Bearings |

Harbin Bearings |

|

This machine is specifically designed for the mass production and quality finishing of:

Automotive Cabin Air Filter Elements

Air Conditioning (AC) Filter Elements

Other pleated media requiring precise side-edge bonding/taping.

1.Innovation over Tradition:

Our spiral wheel system eliminates costly, material-wastingmolds, ensuring immediate ROl and operational flexibility.

2. Unmatched Accuracy:

Servo-driven cutting and PLC control guarantee that every filterelement meets your exact length specifications with uniform glue application.

3. Top-Tier Components:

We partner with leading automation brands like INOVANCE(Huichuan) for superior reliability, control, and ease of maintenance.

4.Optimized for Productivity:

With a production speed of up to 5 pleats per second, this machine is built to maximize your output while saving energy.

Product categories

Product categories