The PP Pleated and Glue Production Line is an integrated, high-precision system designed for the continuous pleating and gluing of polypropylene (PP) filter materials.

This fully automated line combines paper feeding, folding, and hot-melt gluing into one efficient process. With servo control and touch-screen adjustment, it delivers uniform pleats, accurate glue application, and stable performance for producing air, water, fuel, oil and industrial filter elements.

|

Automatic Slitting Paper Feeding Machine

|

|

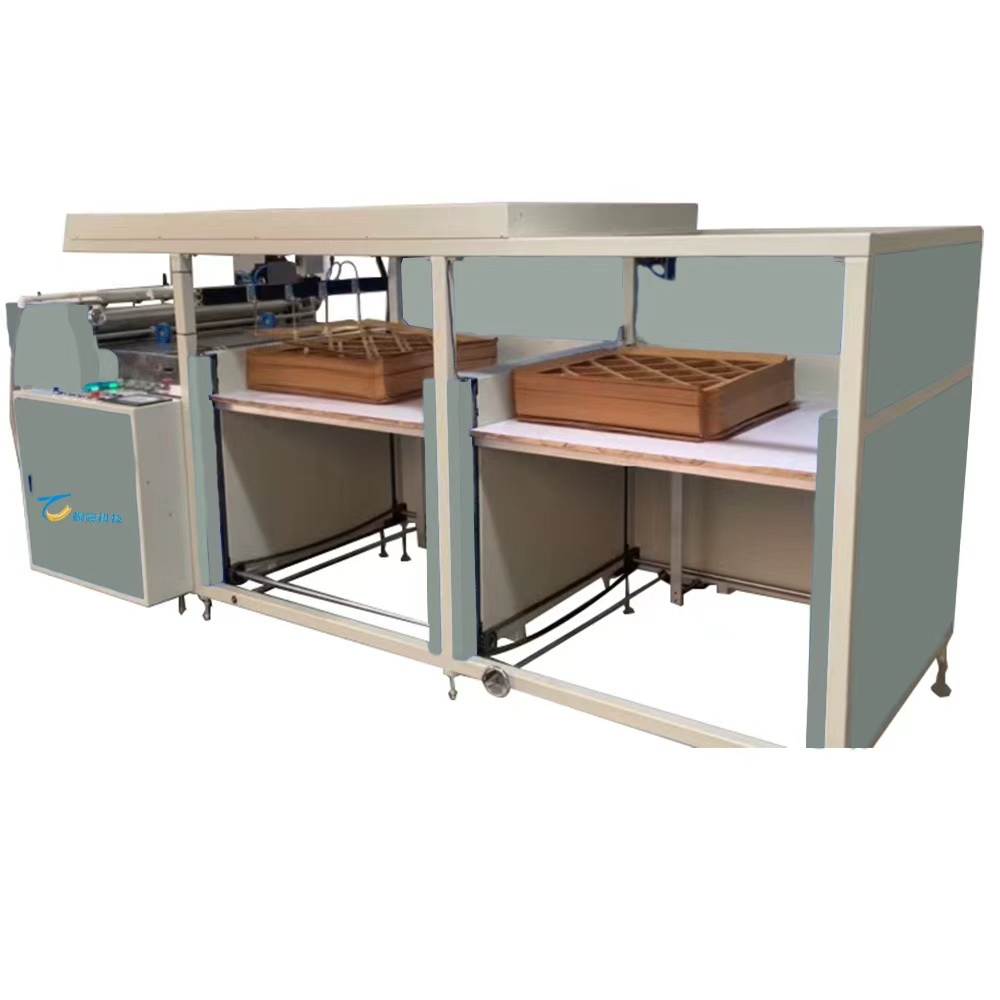

Folding Machine

|

|

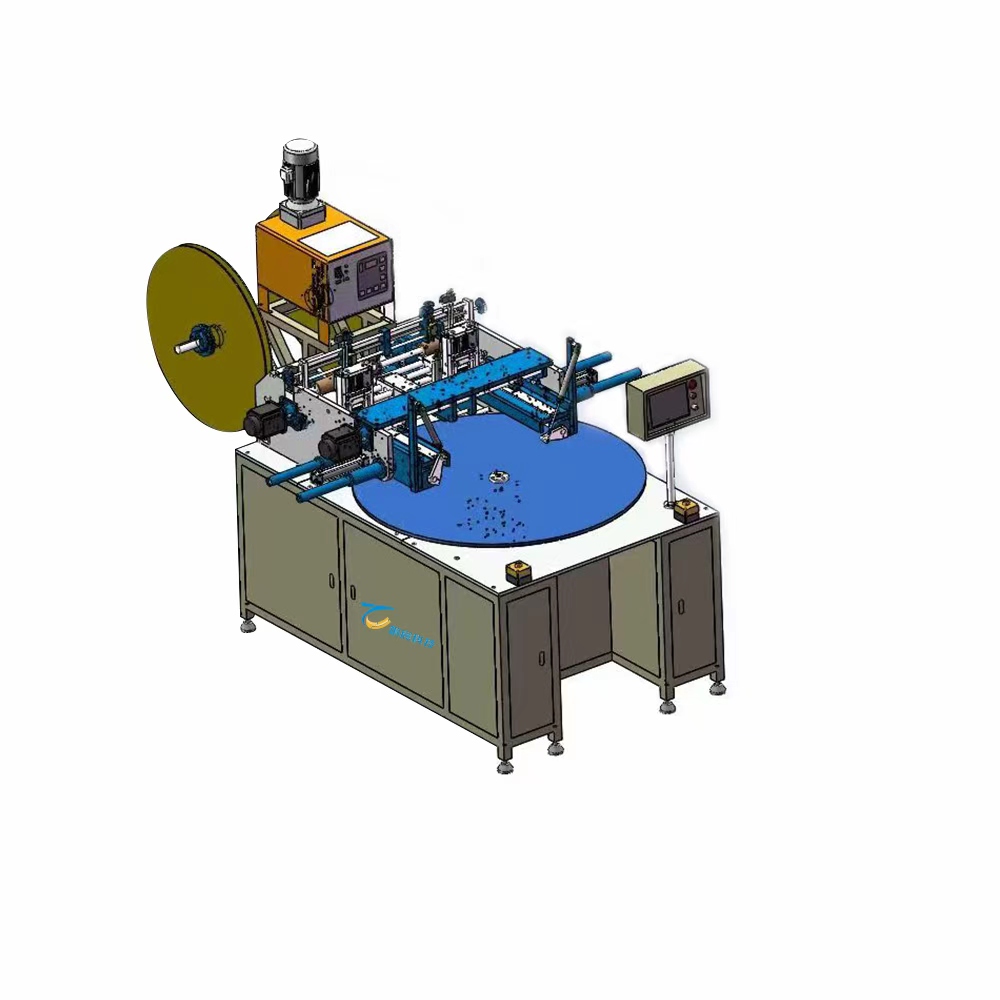

Gluing Machine (55–700 Type)

|

|

Item

|

Specification

|

|

Item

|

Specification

|

|

Item

|

Specification

|

|

Paper Feeding Speed

|

0.5 – 12 m/min (adjustable)

|

|

Maximum Product Width

|

800 mm

|

|

Maximum Product Width

|

700 mm

|

|

Adjustable Filter Paper Width

|

32 – 800 mm

|

|

Adjustable Folding Height Range

|

6 – 55 mm

|

|

Adjustable Folding Height Range

|

6 – 55 mm

|

|

Power Supply Voltage

|

220V / 50Hz

|

|

Folding Speed

|

0 – 100 folds/min

|

|

Production Speed

|

4 – 25 m/min

|

|

Motor Power

|

0.55 kW

|

|

Power Supply Voltage

|

380V / 50Hz

|

|

Gap Between Rubber Strips

|

25.4 mm

|

|

Machine Weight

|

350 kg

|

|

Motor Power

|

1.1 kW

|

|

Number of Rubber Strips

|

2 × 26 (each nozzle controlled by electronic valve)

|

|

Dimensions (L×W×H)

|

1500 × 1300 × 1100 mm

|

|

Preheating Power

|

4 kW

|

|

Power Supply Voltage

|

380V / 50Hz

|

|

|

|

|

Temperature Control Range

|

Room temperature – 200°C

|

|

Total Machine Power

|

13 kW

|

|

|

|

|

Working Air Pressure

|

0.6 MPa

|

|

Working Air Pressure

|

0.6 MPa

|

|

|

|

|

Machine Weight

|

650 kg

|

|

Machine Weight

|

500 kg

|

|

|

|

|

Dimensions (L×W×H)

|

1670 × 1720 × 1240 mm

|

|

Glue Unit Dimensions (L×W×H)

|

160 × 100 × 130 mm

|

|

|

|

|

|

|

|

Main Unit Dimensions (L×W×H)

|

4000 × 130 × 160 mm

|

- Integrated pleating and gluing process with automatic control for continuous operation.

- Equipped with dual 26-point hot melt glue modules and a 50L glue tank, ensuring even adhesive distribution.

- Touch-screen PLC control for real-time adjustment of speed, glue volume, and folding precision.

- Adjustable folding mechanism accommodates various pleat heights and filter materials.

- Servo and stepper motor synchronization ensures stable material feeding and smooth pleat forming.

- Constructed with reinforced aluminum alloy frame for durability and long-term reliability.

This production line is suitable for manufacturing a variety of PP filter materials, including:

- Auto air/ fuel/ oil filters

- Industrial filtration elements

- Water treatment filters

- Automotive filter cores

- HEPA and HVAC filter components

It is ideal for enterprises requiring consistent product quality, high efficiency, and reduced manual labor.

- Fully automated production line minimizes manual handling

- High consistency and precision in pleating and gluing

- Flexible parameter adjustment via intelligent control system

- Low maintenance, robust mechanical structure for long service life

- Suitable for multiple filter materials and production scales

Bengbu Tongchen Automation Technology Co., Ltd. is a professional manufacturer specializing in filter production and automation equipment. We offer customized filtration production solutions backed by years of experience and advanced engineering technology.

Our company is dedicated to:

- Delivering innovative, efficient, and cost-effective equipment.

- Providing professional technical support and after-sales service.

- Ensuring high-quality materials and precision workmanship.

- Helping clients enhance production efficiency and product quality.

Choose Tongchen Automation — your trusted partner in intelligent filter production solutions.

Product categories

Product categories