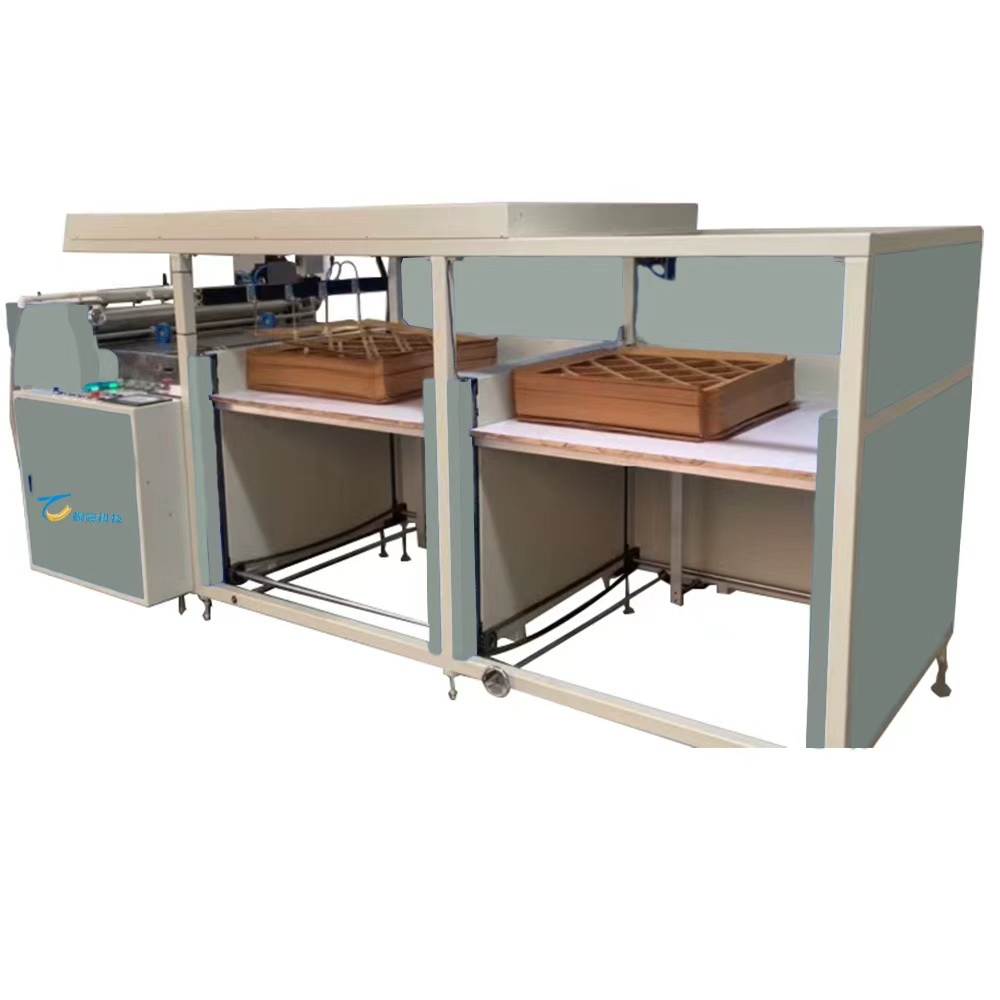

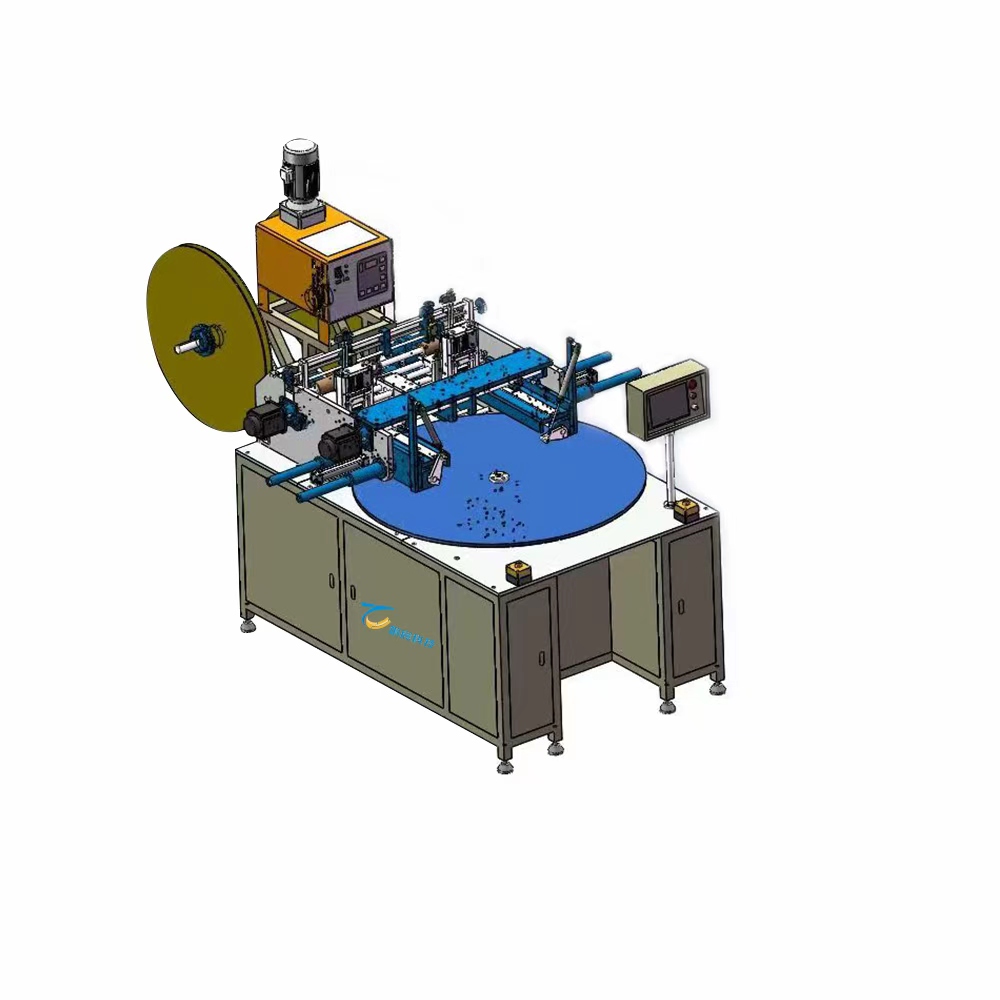

The Thermal Bonding Cotton Inserting Machine integrates automatic feeding, precise inserting, and thermal bonding technology to achieve accurate and stable insertion of cotton and nonwoven filter media.The machine allows flexible parameter adjustment according to different filter structures, ensuring precise media positioning and uniform bonding strength. It enhances the structural stability and filtration performance of filter elements and meets various technical requirements in filter production processes.

-

High Automation Level

Fully automated inserting and thermal bonding process reduces manual operation, significantly improving production efficiency and lowering labor costs.

-

Accurate Media Positioning

Ensures precise insertion of cotton and nonwoven filter media, resulting in consistent filter structure and stable product quality.

-

Strong and Uniform Thermal Bonding

Thermal bonding technology provides reliable and uniform bonding strength, preventing media shifting or loosening during filter operation.

-

Flexible Adjustment for Different Filter Designs

Adjustable parameters allow the machine to adapt to various filter sizes, shapes, and media types, meeting different production requirements.

-

Stable Operation and High Reliability

Designed for continuous industrial operation with stable performance and low failure rate, suitable for mass production.

-

Improved Product Consistency

Machine-controlled processes minimize human error, ensuring high consistency across finished filter elements.

-

Clean and Environment-Friendly Process

Thermal bonding reduces the need for adhesives, helping maintain a clean production environment and comply with industry standards.

-

Easy Operation and Maintenance

User-friendly control system enables easy operation, quick setup, and convenient maintenance.

|

Item

|

Specification

|

| Automatic grade |

Semi-automatic |

| Voltage |

380V |

| Machinery capacity |

3 pcs/min |

| Key machines |

Thermal Cotton Machine |

| Weight |

200kg |

| Brand name |

Tongcheng |

| Dimension(l*w*h) |

1340 X 760 X 1470 mm |

| Place of origin |

China AnHui |

| Filter Element Width |

380 mm |

| Non-Woven Filter Cloth Roll Diameter |

900 mm |

| Total Line Power |

0.46 kW |

| Material frame Size |

500 X 480 X 770 mm |

-

Automotive air and cabin filters

-

Industrial air and dust filters

-

Oil, fuel, and hydraulic filters

-

HVAC filtration systems

-

Customized filter elements

Professional manufacturer specializing in filtration machinery for over 15 years

Advanced control systems ensuring high precision and stability

Customizable solutions based on customer requirements

High-quality materials and long-life machine components

Strong after-sales service with maintenance guidance

Trusted by global filter manufacturers

Product categories

Product categories