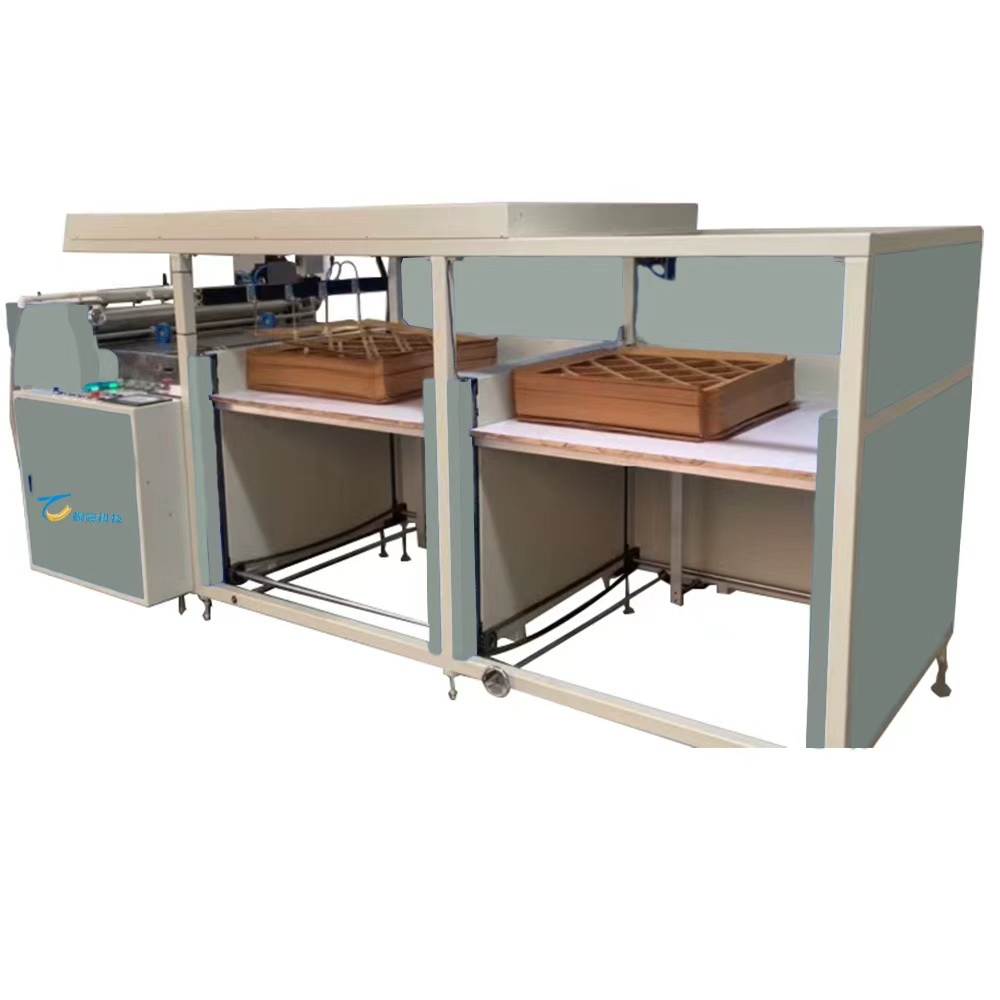

This machine requires no adhesive, ensuring strong bonding, a clean appearance, and compliance with environmental and clean-production standards. It is widely used in the manufacturing of automotive air filters, cabin filters, industrial air filters, and environmental filtration products. With precise control of temperature, pressure, and time, it delivers high forming consistency and production efficiency, making it a key piece of equipment in modern eco-friendly air filter manufacturing.

- Eco-friendly, adhesive-free process:Uses heat sealing or heat forming instead of chemical adhesives, reducing VOC emissions and meeting environmental requirements.

- Strong bonding and high consistency:Precisely controlled temperature, pressure, and time ensure reliable bonding and stable, consistent filter shaping.

- Compatible with various eco-friendly filter materials:Suitable for non-woven fabrics, composite media, and synthetic fiber filter materials.

- Adjustable and precise process control:Independent adjustment of temperature, pressure, and sealing time to meet different filter designs and material properties.

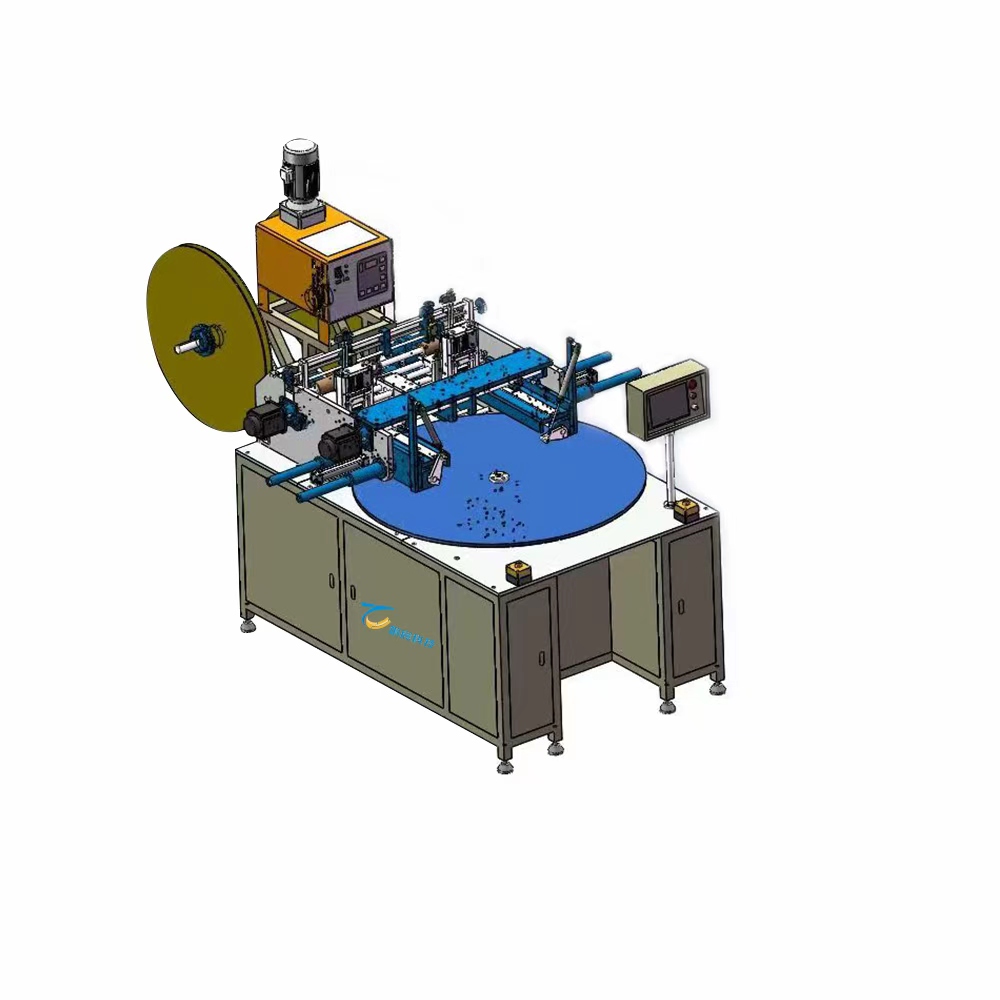

- High level of automation:Equipped with PLC and touch-screen control systems for easy operation and continuous mass production.

- High production efficiency:Fast heat forming speed and easy integration with pleating, trimming, and other filter production equipment.

- Clean appearance and stable quality:Smooth, neat sealing areas with no glue residue or odor, enhancing product quality.

- Stable operation and easy maintenance:Robust structure, reliable performance, and simple maintenance suitable for long-term industrial use.

- High process stability and long-term consistency

The heat forming process is driven by machine parameters rather than operator experience, ensuring stable performance and consistent product standards over long-term operation. This makes quality control and standardized production easier to manage.

- Reduced dependence on skilled labor

With clear operating procedures and programmable settings, the machine runs automatically once parameters are set, minimizing the impact of operator skill levels and reducing training requirements.

- Significantly improved production yield

Controlled heat sealing helps prevent common defects such as weak bonding, misalignment, and structural deformation, effectively reducing scrap and rework.

- Predictable and manageable production cycle

The forming process does not rely on curing or waiting time, resulting in a stable cycle time that supports accurate capacity planning and delivery scheduling.

- Simplified production flow with fewer intermediate steps

Heat sealing and forming are completed in a single process, reducing material handling, temporary storage, and secondary operations, leading to a more efficient workflow.

- Low sensitivity to production environment

The equipment is less affected by changes in temperature and humidity, enabling stable operation throughout different seasons and factory conditions.

|

Item

|

Specification

|

| Product capability: |

70pcs /min |

| Temp.control scope |

normal temp.~300oC |

| Working air pressure |

0.8MPa |

| Heating power |

6kw |

| Power supply |

380V/50Hz |

| Machine weight |

700kg |

| Machine size |

1000×1050×2500mm(L×W×H) |

- Automotive Air Filters

- Industrial Air Filters

- Building & HVAC Air Filters

- Environmental & Air Purification Equipment

- Specialized Air Filtration Applications

Professional manufacturer specializing in filtration machinery for over 15 years

Advanced control systems ensuring high precision and stability

Customizable solutions based on customer requirements

High-quality materials and long-life machine components

Strong after-sales service with maintenance guidance

Trusted by global filter manufacturers

Product categories

Product categories