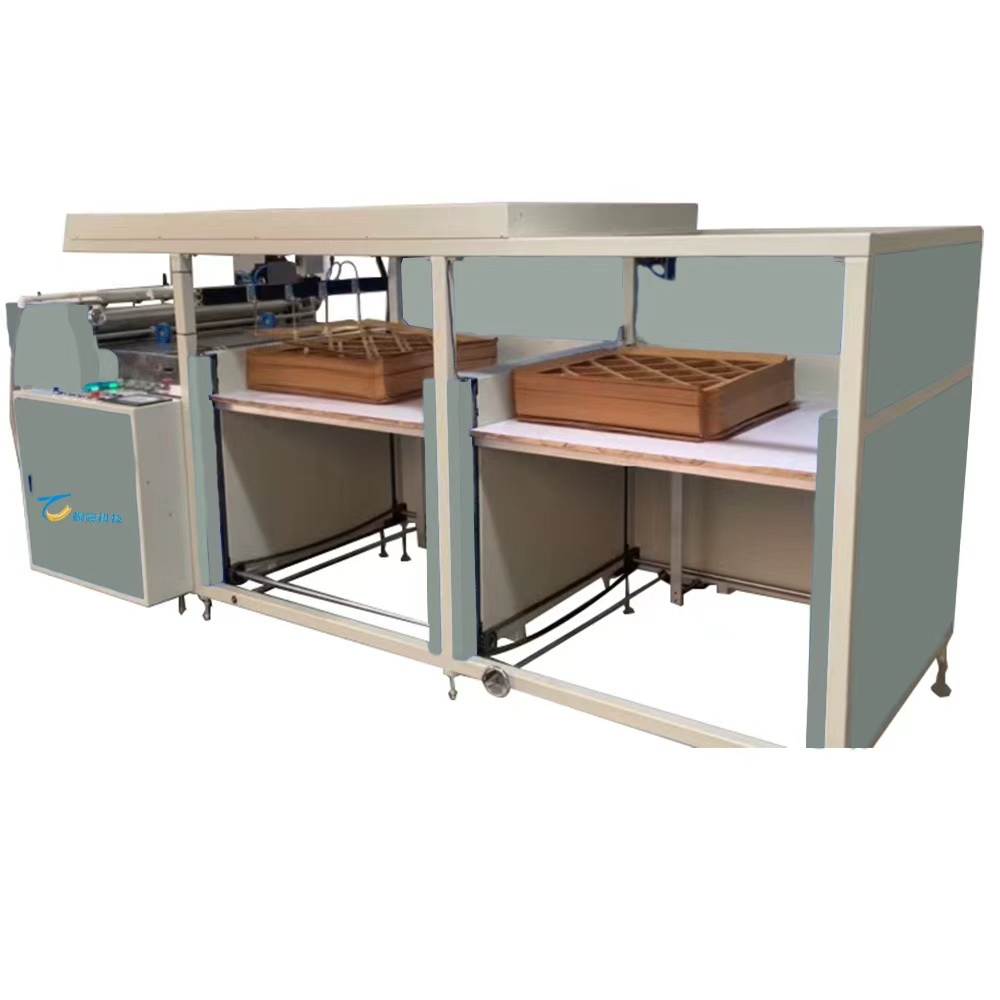

The Fully Automatic PP Intermittent Gluing Production Line is primarily used for applying adhesive (bonding) to polypropylene (PP) filter elements or other material filter elements within the filter industry. This production line is designed to enhance production efficiency, improve product quality, and reduce labor costs, particularly in areas requiring precise adhesive application. It ensures uniform adhesive distribution and secure bonding.

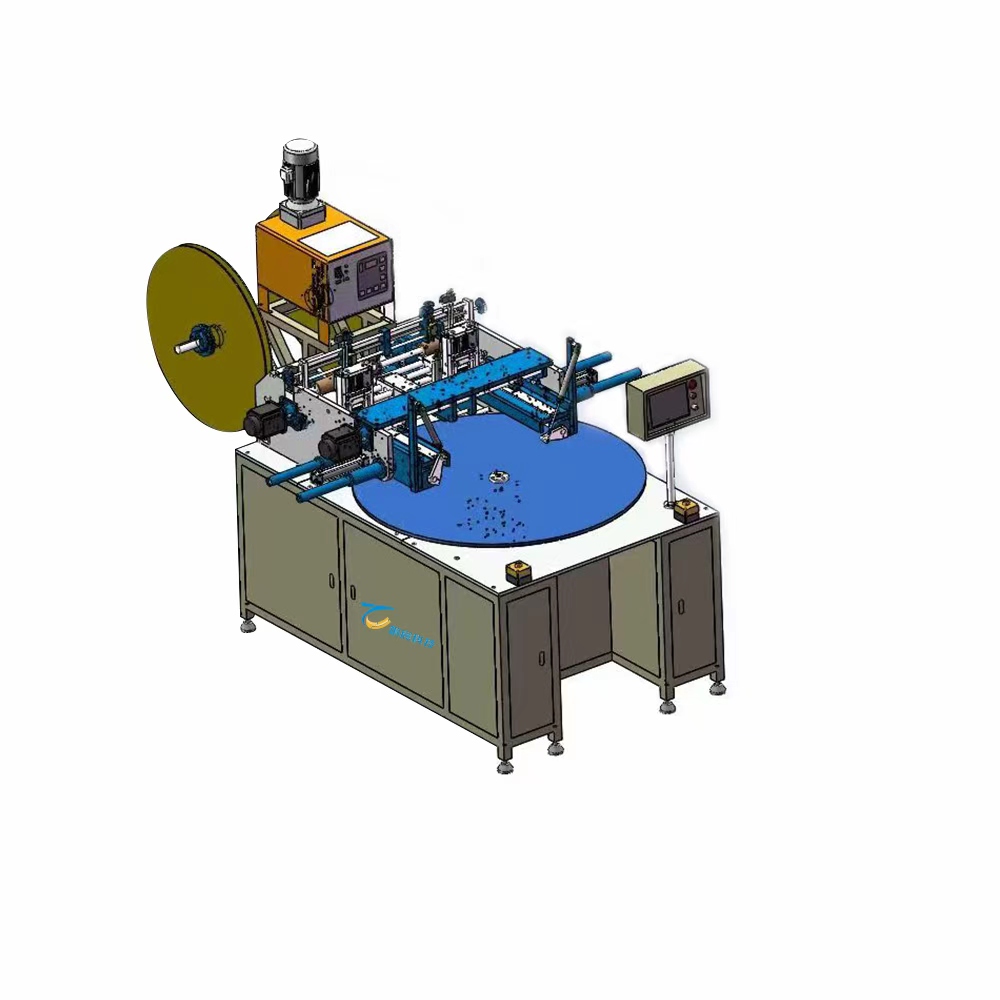

1. Adhesive application system comprises one 50kg hot melt adhesive machine and two sets of 36-point independent adhesive nozzle assemblies.

2. equipped with 52 solenoid valves controllable via the main unit's touchscreen,

3. Rotation speed, paper folding speed, conveyor belt speed, and adhesive application methods are all controlled by the computer touchscreen,

4. Glue gun spray performance: continuous spraying, single-sided/double-sided application, surface glue cutoff, and folding after a specified amount of adhesive application;

5. The folding and wave-forming mechanism is adjustable vertically and horizontally, accommodating filter cores of various specifications and heights.

6. Speed control: Automatically adjustable via computer using a servo control system to synchronize folding and conveyor belt speeds, enabling precise control of adhesive-to-paper and paper-to-paper spacing.

1. Motor Configuration: Servo motor, Brand: INOVANCE (Huichuan), Reducer: Brand: NSD

2. Touchscreen Configuration: 10-inch touchscreen, Brand: INOVANCE (Huichuan) Weintek;

3. PLC Programmable Controller Configuration: Brand: INOVANCE (Huichuan), Servo Drive: Brand: INOVANCE (Huichuan)

4. Pneumatic Components: Cylinders, Solenoid Valves, Pressure Regulators: Brand: Shanghai Shannaisi; Bearings: Brand: Harbin Bearing

5. General Electrical Components: Custom high-precision proximity switches, imported standard proximity switches, relays, and other small electrical components

6. Mechanical Parts: Reinforced aluminum profile frame; Shafts undergo electroplated hard chrome plating; Other parts feature decorative hard chrome plating or standard blackening treatment;

7. Process Flow: Feeding, gluing mechanism, nozzle closure, upper/lower fans, folding mechanism, transmission unit, synchronous belt, aluminum shaft conveyor.

8. Instrumentation Standard Components: All instruments installed rationally for easy disassembly.

| Item |

Specification |

| Maximum product width |

900mm

|

| Adjustable fold height range |

6–80mm (depending on material)

|

| Production speed |

4–15m/min

|

| Glue strip spacing |

25.4mm

|

| Number of glue strips |

2×36strips, each glue nozzle controlled by an electronic valve. Features automatic adhesive cutoff function.

|

| Power supply voltage |

380V/50Hz |

| Total machine power |

15kW |

| Operating air pressure |

0.6MPa

|

| Machine weight |

500kg

|

| Adhesive Applicator Dimensions |

1000×800×1500mm (L×W×H)

|

| Main Unit Dimensions |

4000×1600×1750mm (L×W×H)

|

This production line is ideal for gluing:

-

HVAC air filter material

-

Medium-efficiency & high-efficiency filter papers

-

Meltblown + nonwoven composite filter materials

-

Automotive air filter elements

-

Industrial dust filtration media

-

Purification equipment filter paper

-

Multi-layer pleated filter material

Suitable for factories in: air purification, cleanroom systems, automotive parts, household appliances, industrial filtration, and environmental protection industries.

-

Professional Manufacturer with years of experience in filter machine production

-

Full-servo control system using INOVANCE high-precision components

-

Strong R&D capability supporting customization and special material requirements

-

High reliability with reinforced mechanical design & premium accessories

-

Comprehensive after-sales service including installation, training, and maintenance

-

Stable global supply with machines exported to multiple countries

-

Competitive pricing with factory direct sale advantage

Product categories

Product categories