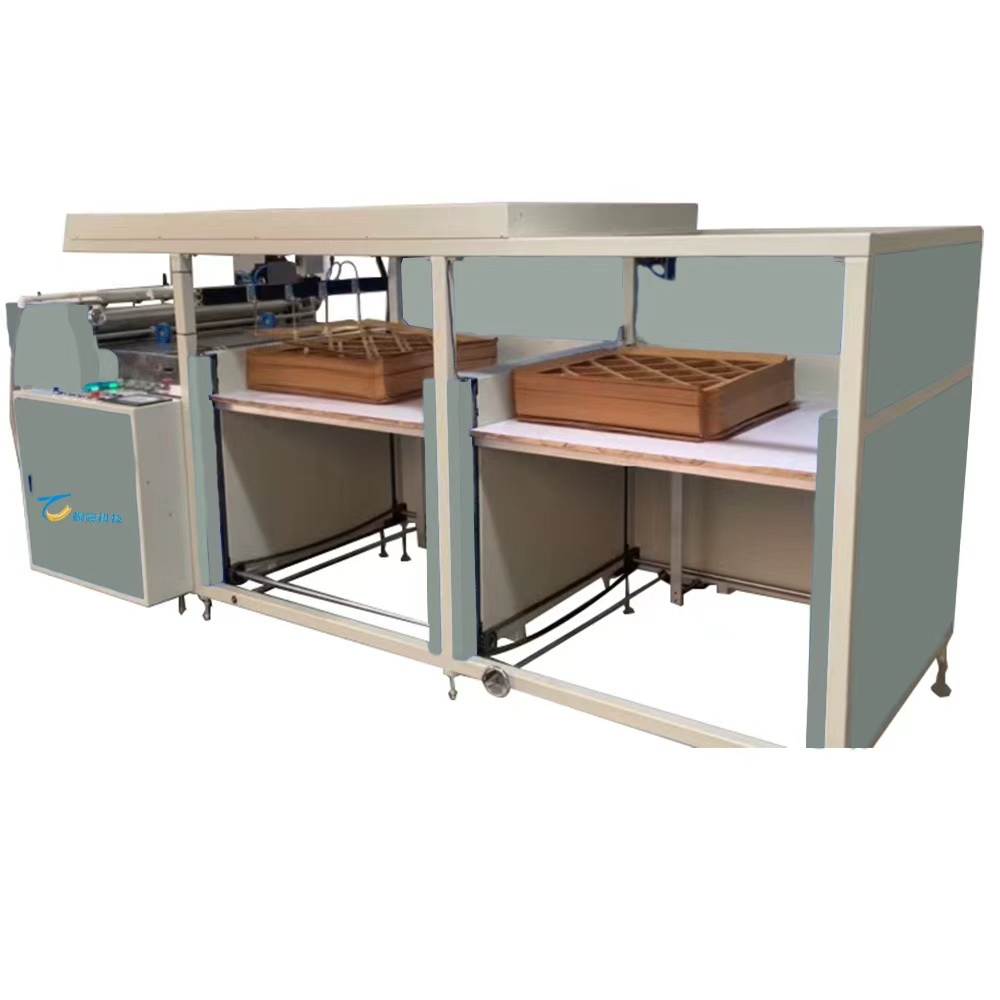

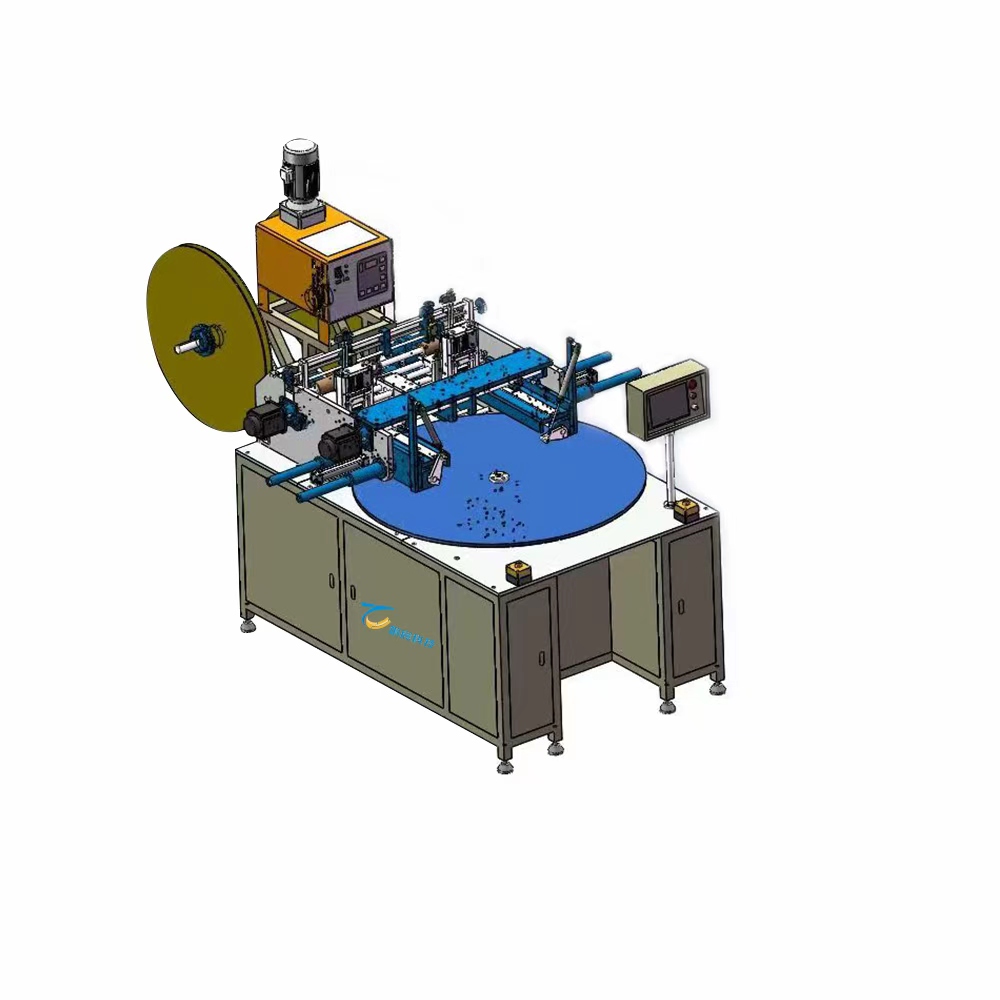

This Double-Sided Edge-Gluing Machine delivers fully automated tape pulling, hot melt adhesive coating, precision cutting, feeding, and standby return. Operators only need to attach the adhesive-coated strip to the product, making the entire process efficient, stable, and easy to operate.

With a digital stepper motor, variable-speed drive, 7-inch touchscreen, and Delta PLC control, the machine ensures precise adhesive output with adjustable gluing thickness from 0.5–2.5mm. Dual-side simultaneous gluing increases productivity significantly while maintaining stable adhesive thickness and uniform bonding.

Its robust mechanical structure, chrome-plated shafts, reinforced aluminum alloy frame, and rational component layout provide durability, easy maintenance, and consistent working performance.

- Full Touchscreen Control – 7-inch interface for easy adjustment of length, mode switching, and parameters.

- Dual-Side Operation – Left and right sides work simultaneously to double production efficiency.

- Flexible Production Modes – Continuous, single-cycle, manual, and auto modes with fast changeovers.

- Automated Workflow – Automatic tape pulling, adhesive application, cutting, feeding, and returning.

- Uniform Glue Thickness – Adjustable 0.5–2.5mm with ±0.3mm end tolerance.

- Rapid Hot Melt Curing – Ensures fast setting while saving energy.

- Durable Mechanical Design – Chrome-plated shafts and reinforced aluminum alloy frame.

- Multi-Length Compatibility – Supports different product lengths at the same time.

- High Efficiency: Dual-side gluing improves output and reduces manual labor.

- Energy Saving: Hot melt adhesive quick-curing system reduces power consumption.

- Strong Flexibility: Suitable for long, short, and mixed-length products.

- Precision Control: Delta PLC + digital stepper motor ensures stable and accurate feeding.

- Easy Maintenance: Logical component arrangement for easy disassembly and inspection.

- Stable Temperature Control: Reliable hot melt system ensures consistent adhesive quality.

- Premium Build Quality: Industrial-grade materials support long-term operation.

|

Item

|

Specification

|

|

Glue Dispenser Capacity

|

10 kg

|

|

Glue Hose Length

|

1.5 m per hose

|

|

Glue Nozzle

|

1 unit

|

|

Stepper Motor

|

1 unit (Brand: SAIT)

|

|

Variable Speed Motor

|

1 unit

|

|

Edge Strip Adhesive Thickness

|

0.5–2.5 mm (±0.3 mm tolerance)

|

|

Cutter Blade Length

|

100 mm

|

|

Glue Nozzle Width

|

10–100 mm

|

|

Melting Temperature

|

≤ 200°C

|

|

Power Supply

|

220V, 50Hz

|

|

Total Power

|

6 kW

|

|

Air Pressure

|

0.6 MPa

|

|

Main Machine Dimensions

|

2455 × 1150 × 1250 mm

|

|

Glue Machine Dimensions

|

800 × 500 × 1200 mm

|

|

Touchscreen

|

7” WEINTEK HMI

|

|

PLC

|

Delta (Taiwan)

|

|

Mechanical Structure

|

Chrome-plated shafts + reinforced aluminum alloy

|

Ideal for industries requiring precise, consistent adhesive edge sealing:

- Air filters

- Cabin and HVAC filters

- Paper frame filters

- Packaging edge sealing

- Industrial panel sealing

- Automotive interior edge sealing

- Foam, EVA, and nonwoven edge bonding

- Multi-length adhesive strip production

Professional Manufacturing Expertise with extensive experience in fully/semiautomatic gluing equipment.

Advanced Control System featuring international-grade PLC and touchscreen technology.

High Cost-Performance Ratio offering superior quality at competitive prices.

Stable & Durable Structure built for long-term industrial operation.

Efficient Support & Customization available for different edge widths, adhesive types, and production requirements.

Reliable After-Sales Service including training, installation guidance, and lifetime technical support.

Product categories

Product categories