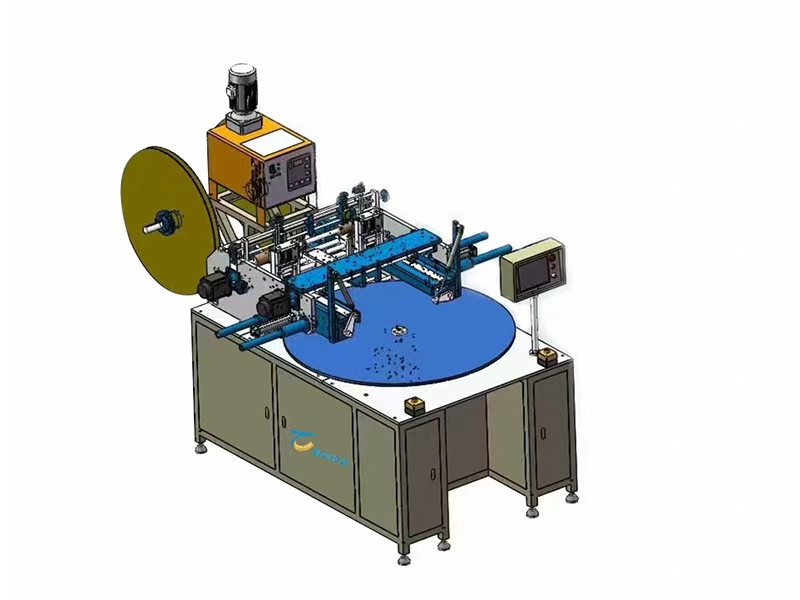

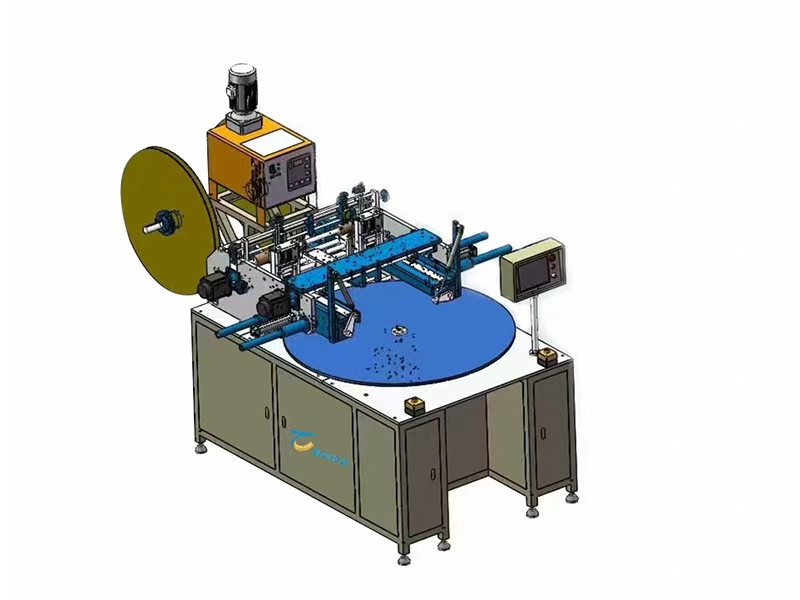

This Fully Automatic Rotary Edge-Gluing Machine integrates automated feeding, positioning, edge banding, trimming, and cooling into a single high-performance unit. The rotary table mode allows operators to simply place the material onto customized molds, after which the machine automatically applies adhesive, bonds the edge strip, and cuts to length.

Equipped with a 30L hot melt adhesive machine, dual glue scraping modules, and industrial-grade mechanical components, the system offers stable operation, high productivity (2–8 pcs/min), and accurate gluing width control. It is suitable for various folded filter elements and edge band applications in filtration manufacturing.

- Rotary Table Automation – Operators only place the product; the machine handles gluing, bonding, and trimming automatically.

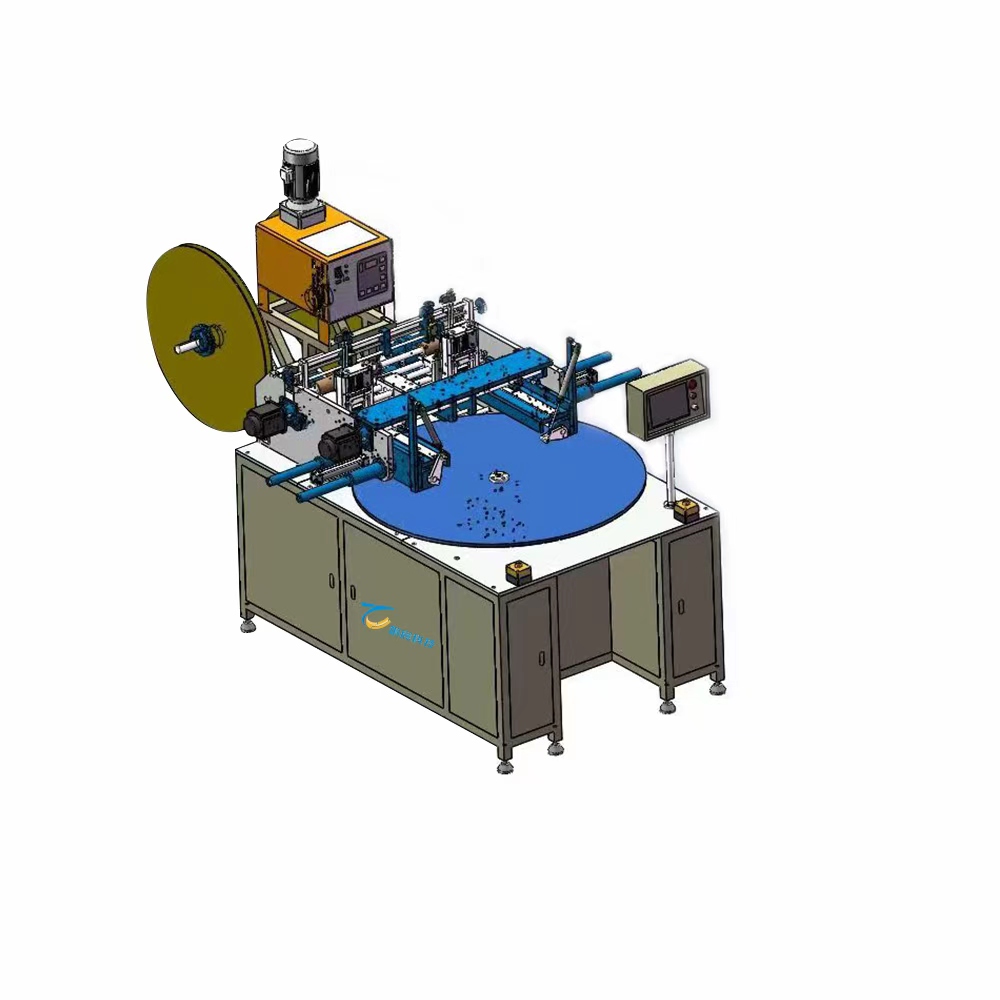

- High Precision Control – INOVANCE five-axis PLC ensures stable, accurate motion coordination.

- Flexible Size Compatibility – Supports folding widths from 120–350mm and folding heights from 15–55mm.

- Adjustable Gluing Width – Edge strip gluing width adjustable from 15–60mm for different filter specifications.

- Efficient Hot Melt Adhesive System – Large 30L glue tank provides continuous operation with quick material supply.

- Automatic Cooling System – Ensures glue line stabilization and improves final bonding quality.

- Industrial-grade Structure – Heavy-duty profiles, chrome-plated shafts, and durable black-oxide-treated components.

- Easy Maintenance & User-Friendly – Simple operation interface, easy mold change, and robust parts ensure long service cycles.

- High Productivity: 2–8 pieces per minute for efficient large-scale manufacturing.

- Labor-Saving: Greatly reduces manual gluing and trimming work.

- Consistent Quality: Automatic glue control delivers uniform adhesive distribution.

- Durable Build: Premium materials and surface treatments ensure long-term stability.

- Precision Engineering: Stepper motor control improves stability and reduces positioning errors.

- Cost-Effective: Reduces glue waste and improves overall manufacturing yield.

|

Item

|

Specification

|

|

Equipment Specifications

|

Max folding width 120–350mm

|

|

Filter Folding Height

|

15–55mm

|

|

Production Speed

|

2–8 pcs/min

|

|

Stepper Motors

|

0.75 kW × 2 sets

|

|

Edge Strip Gluing Width

|

Adjustable 15–60mm

|

|

Hot Melt Glue Machine Capacity

|

30L

|

|

Edge Strip Width

|

15–60mm

|

|

Power Supply

|

380V / 50Hz

|

|

Total Power

|

15 kW

|

|

Machine Dimensions

|

2600 × 1700 × 1900 mm (L×W×H)

|

|

Glue Machine Preheating Time

|

30 minutes

|

|

Cooling Method

|

Automatic cooling

|

|

Control System

|

INOVANCE PLC, five-axis control

|

|

Glue System

|

1×30L hot melt machine + 2 glue scraping systems

|

|

Structural Materials

|

Thickened aluminum/iron profiles, chrome-plated shafts

|

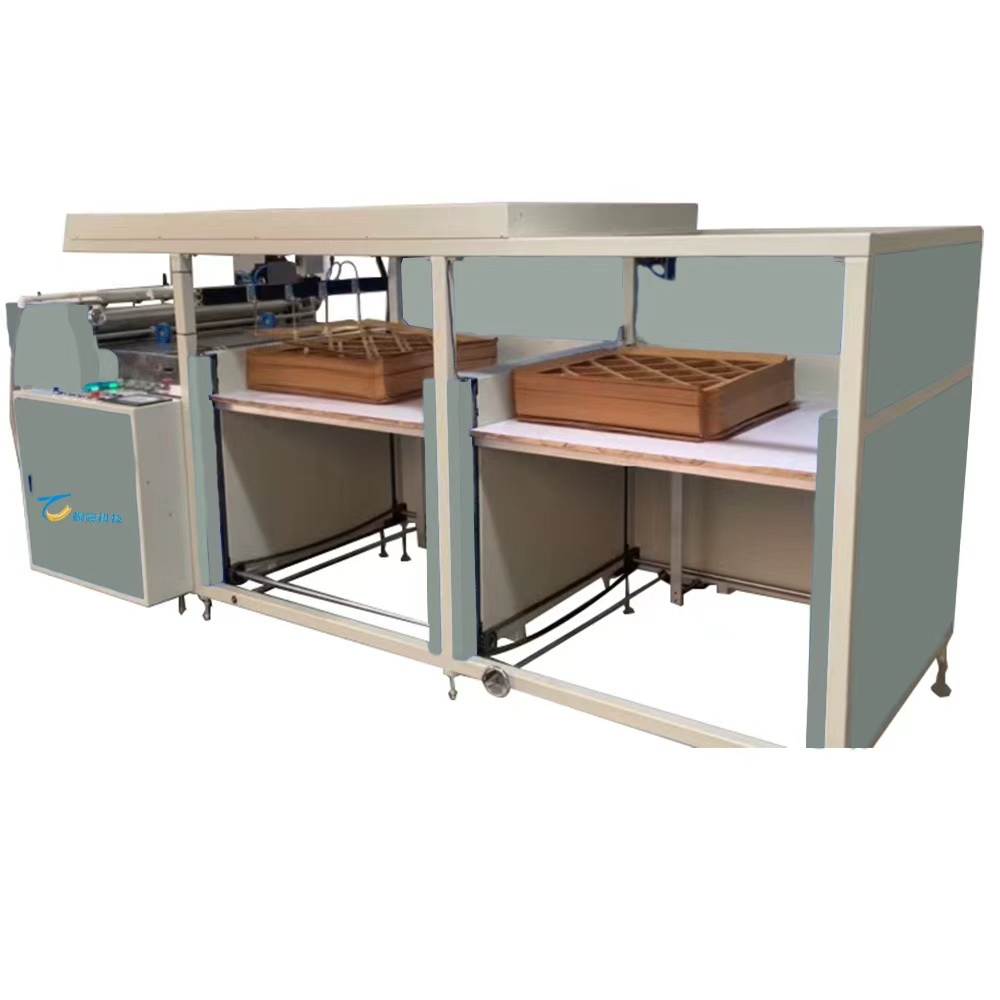

This machine is widely used in the filtration and HVAC industry, suitable for:

- Air filter elements

- Folded paper filters

- Industrial filtration cartridges

- Cabin air filters

- Environmental and dust-removal filters

- Precision edge banding applications for folded materials

Ideal for manufacturers of medium/high-efficiency filter elements and various edge-sealing products.

Professional Filtration Equipment Manufacturer with years of automation experience.

Customized Solutions available for different filter specifications.

Reliable Quality Control with premium components and strict manufacturing standards.

24/7 Technical Support and comprehensive after-sales service.

High Cost-Performance compared to similar international brands.

Proven Performance in factories worldwide with stable long-term operation.

Product categories

Product categories