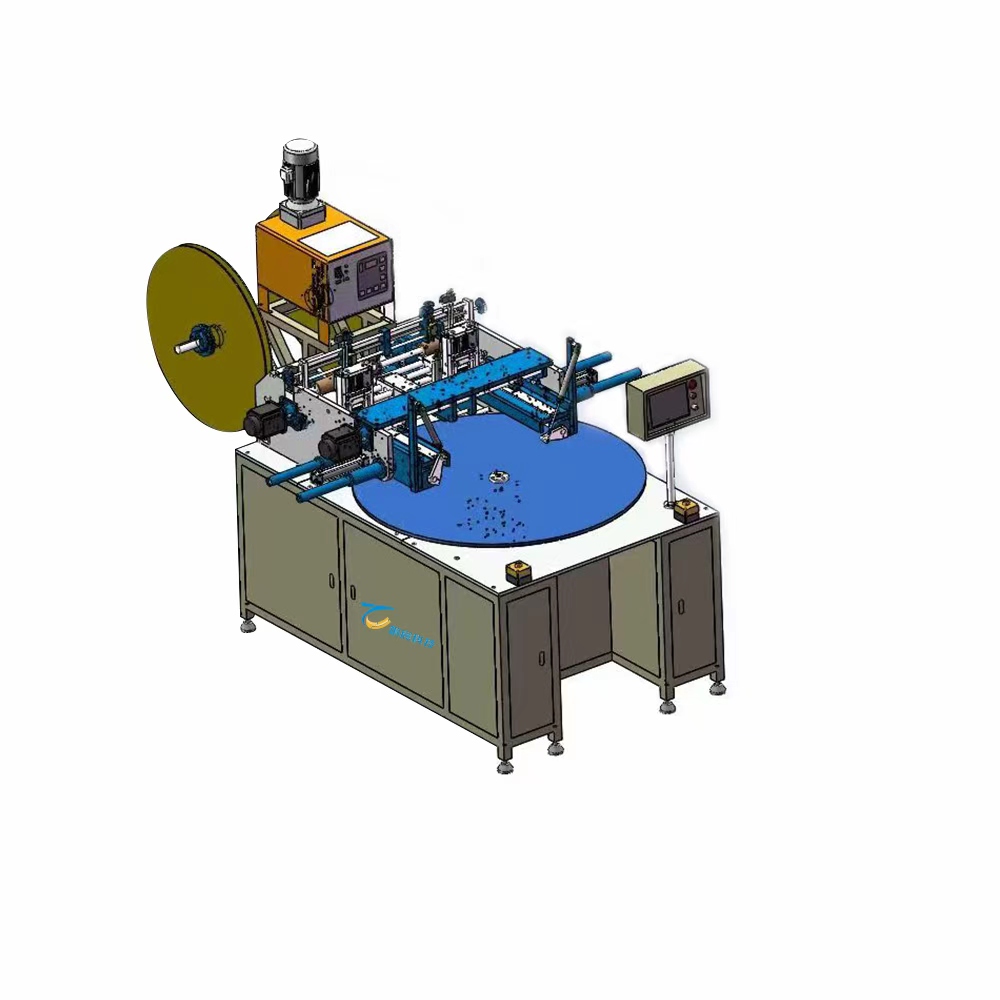

The TCPU-20F is an advanced automatic casting machine specially developed for PU sealing and packing of filter elements. Equipped with a three-layer sealed tank, imported metering pump, intelligent control system, and a universal automatic workbench, the machine performs high-speed, accurate, and consistent PU dispensing.

With adjustable mixing ratios, programmable pouring, automatic head retraction, and support for multiple product shapes, the TCPU-20F delivers outstanding casting precision and production efficiency. It is ideal for automotive air filters, industrial filters, and high-volume production lines requiring consistent quality.

Digital instrument display with computerized operation.

Stable and precise metering with automatic temperature control.

Innovative tank structure with non-polar mixing adjustment.

Unique head design with precision reflow fine-tuning.

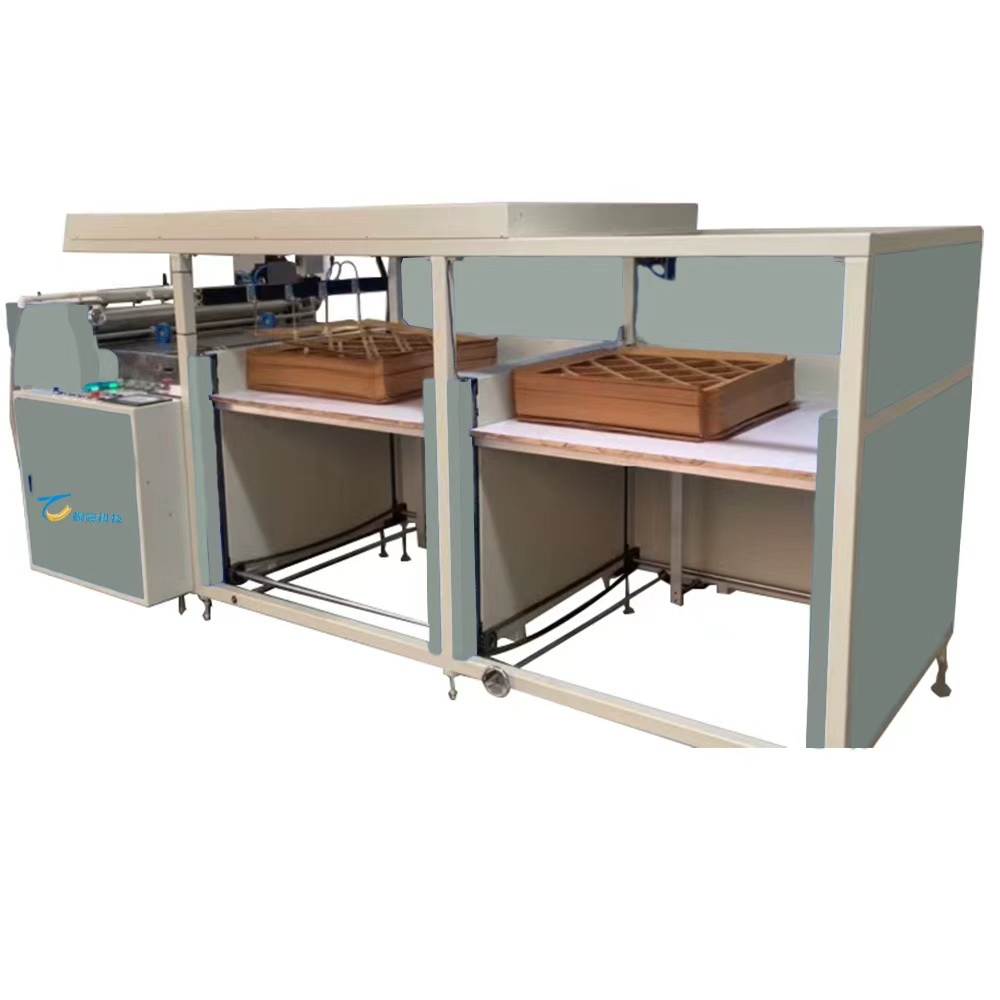

Equipped with X-Y axis rotary workbench, capable of casting square, round, and irregular-shaped air filters.

High accuracy PU dispensing with imported metering pump

Automatic pouring control for consistent sealing quality

Supports multiple shapes including round, square, and special-shaped filters

Low maintenance stainless steel tank with efficient temperature regulation

Improved productivity with automatic head switching and cleaning

Suitable for automotive manufacturing requiring stable and repeatable results

Main Components of the Equipment

Tank: A three-layer stainless steel sealed tank with stirring and automatically constant temperature.

Pump: Low-speed, high-precision imported metering pump and precise transmission and display devices.

Head: Automatic three-position switching (pouring, reflux, cleaning); pneumatic displacement with programmable automatic cleaning after pouring.

Workbench: Automatically controlled universal workbench for circular, square, or special-shaped filter core pads.

Control System: Temperature, pressure, and casting volume automatically regulated.

|

Item

|

Specification

|

|

Total Discharge Rate

|

10–40 g/s

|

|

Mixing Ratio

|

A:B = 1–2:1 (adjustable)

|

|

Automatic post-pouring head retraction distance

|

450mm

|

|

Max pouring size (square cores)

|

400×300mm (L×W)

|

|

Max pouring diameter (circular cores)

|

350mm

|

|

Movement speed

|

2–10 m/min

|

|

Total power consumption

|

8kW

|

|

Power supply voltage

|

380V/50Hz

|

|

Machine weight

|

1000kg

|

|

Machine dimensions

|

1500×2000×2100mm (L×W×H)

|

The TCPU-20F Full-auto Casting Machine is primarily used for PU casting and sealing of various filter elements. It is suitable for:

Automotive air filters, including engine and cabin filters

Industrial air filters and dust collector filter elements

HVAC and environmental protection filters

Round, square, and irregular-shaped filter cores requiring PU gasket or sealing

Its flexible X-Y axis workbench and precise PU metering system make it ideal for manufacturers producing PU-sealed filter elements in medium to large-scale production.

Advanced automatic PU casting technology

High stability and accuracy with imported metering system

Capable of handling multiple filter shapes and dimensions

Intelligent control system ensures consistent production quality

Strong mechanical structure for long-term durability

Professional support for filter production lines

Product categories

Product categories